20+ Years Experience

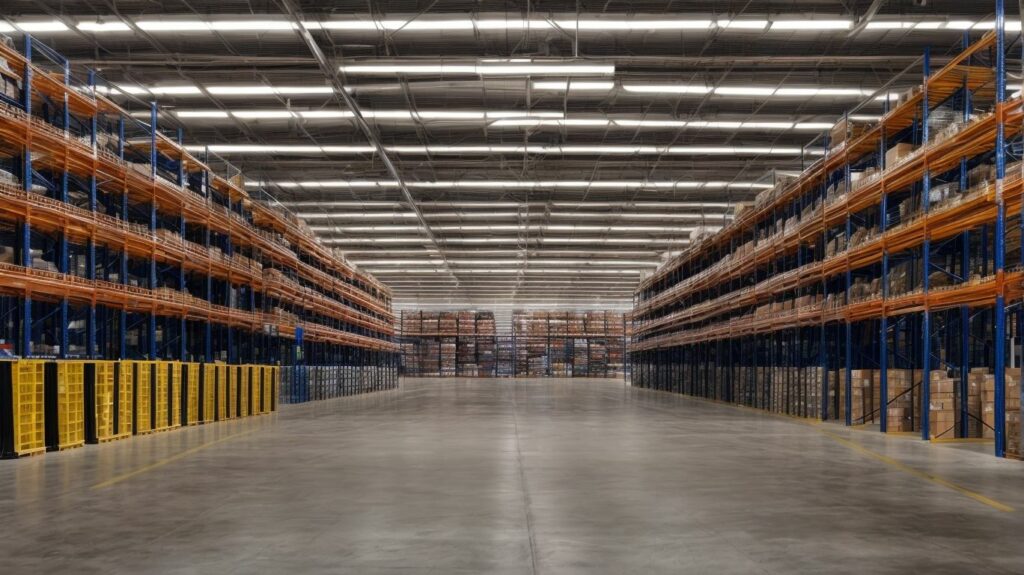

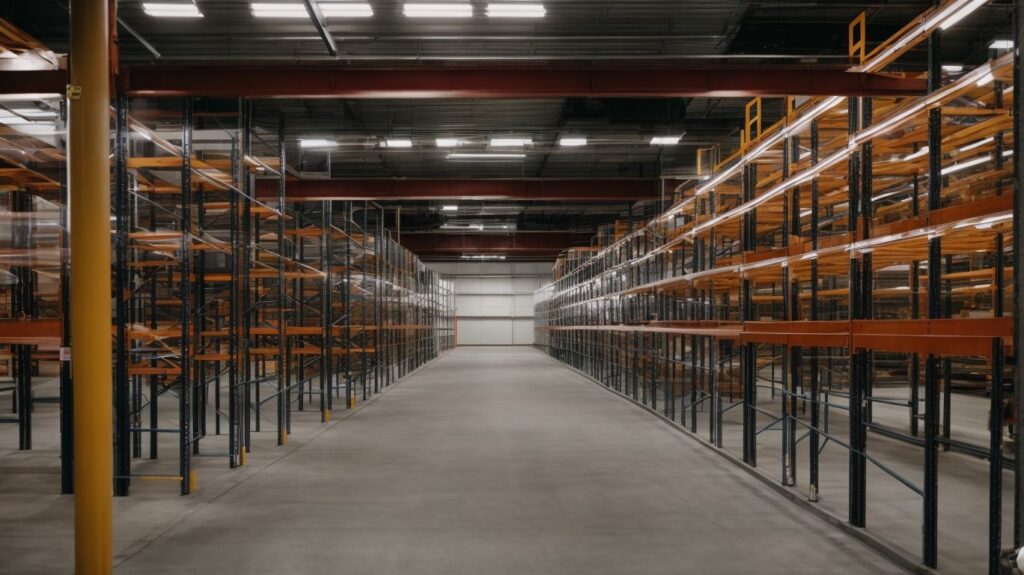

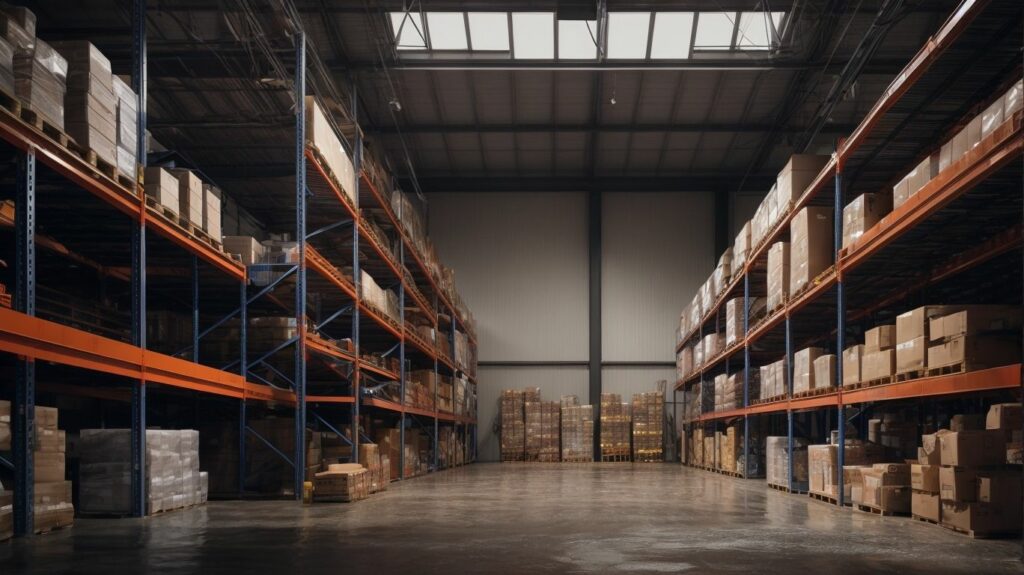

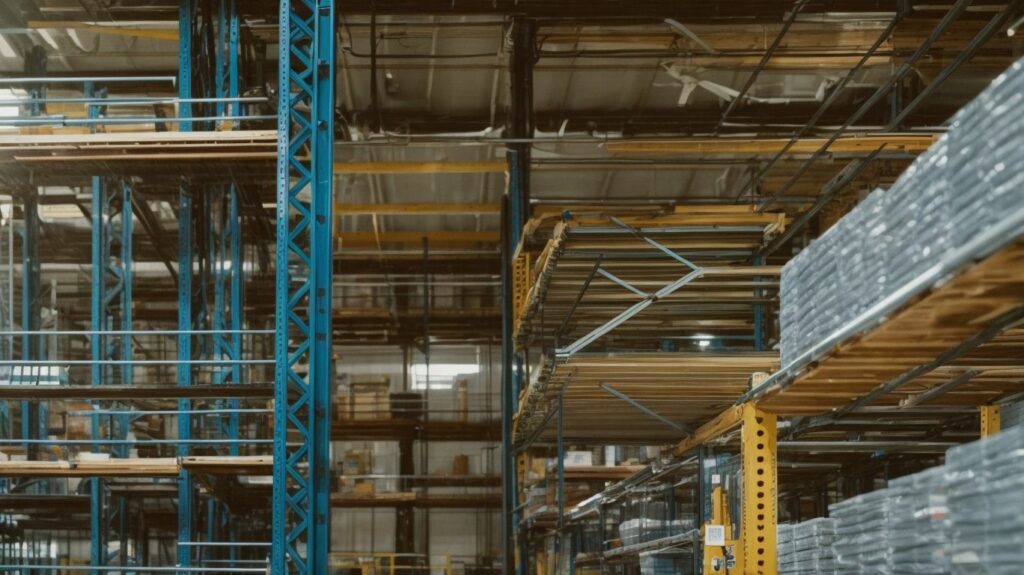

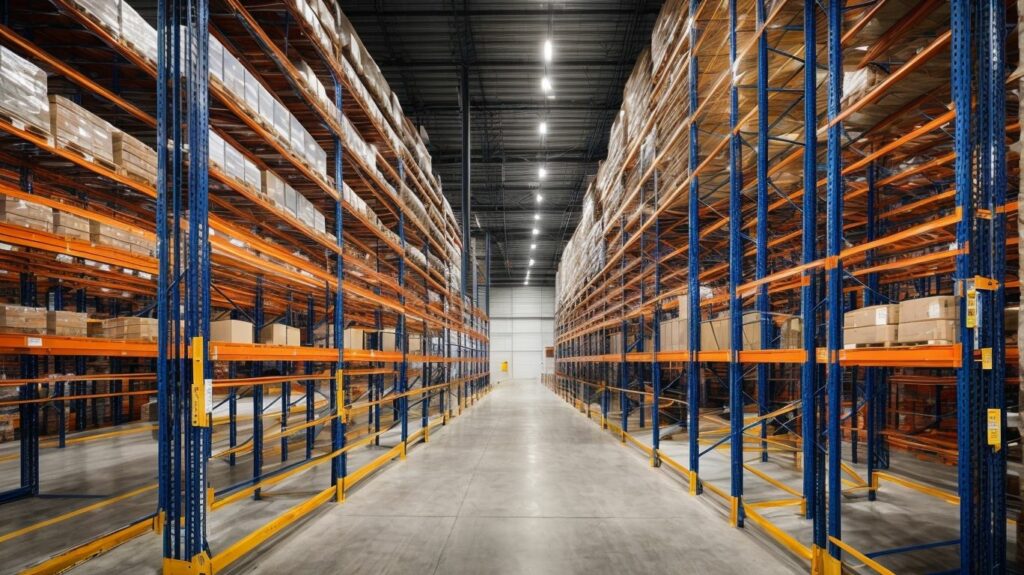

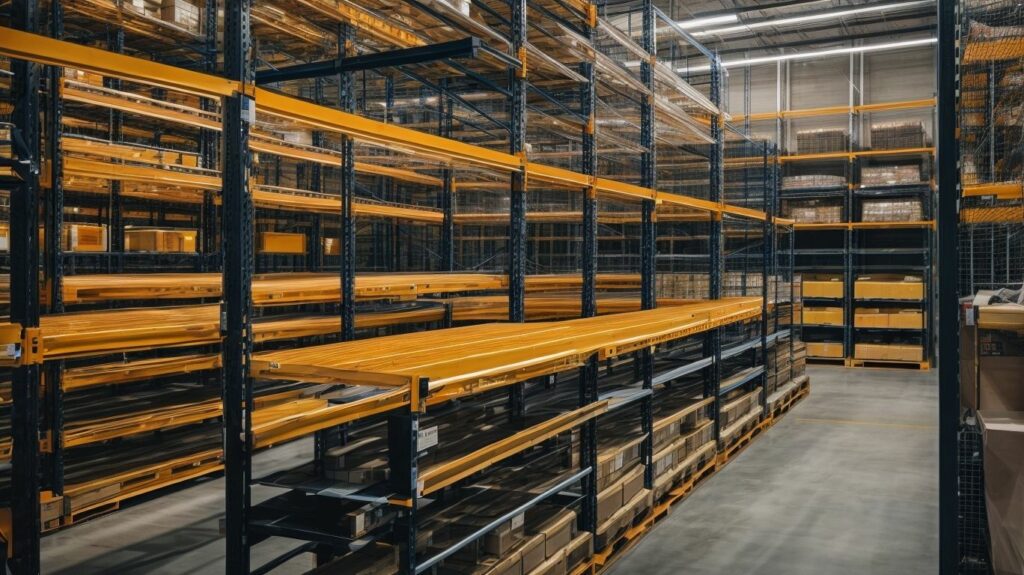

Specialist Pallet Racking

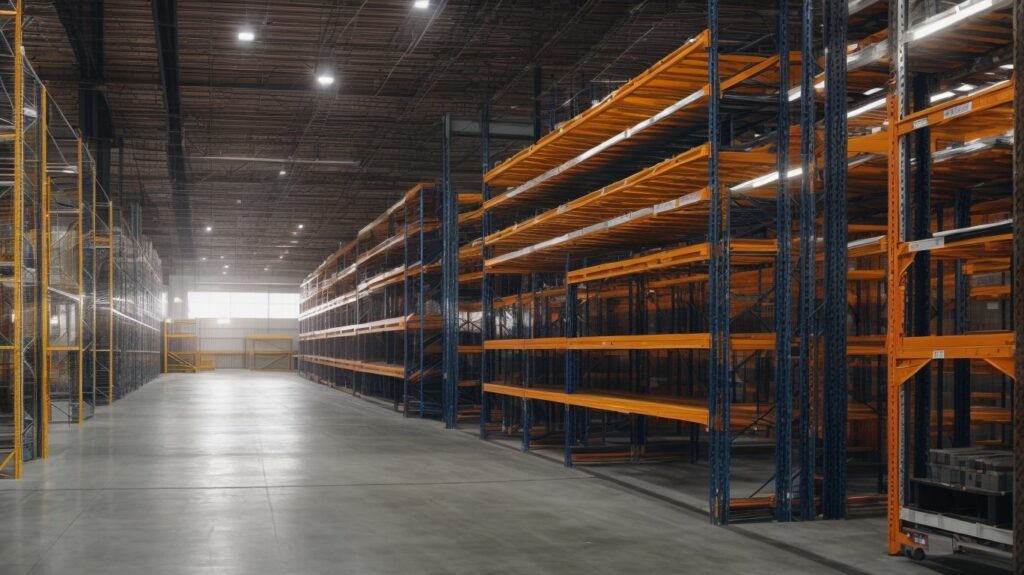

SEMA Inspectors play a crucial role in ensuring the safety and compliance of warehouses and storage systems. SEMA, an acronym for the Storage Equipment Manufacturers’ Association, is a leading authority in the field of storage systems and warehouse safety. SEMA Inspectors, as experts in their field, have the responsibility of conducting inspections, ensuring compliance with safety regulations, providing training and guidance to businesses, and reducing workplace accidents. Being a SEMA Inspector requires in-depth knowledge of safety regulations and excellent attention to detail. The importance of SEMA inspections for businesses cannot be overstated, as they help maintain warehouse safety, reduce accidents, and prevent legal consequences.

SEMA inspectors are professionals who specialize in conducting safety inspections on vehicles and equipment used in the automotive industry. They are responsible for ensuring that these vehicles and equipment meet the required safety standards and regulations. SEMA inspectors have extensive knowledge and training in areas such as vehicle mechanics, electrical systems, and safety features. They conduct thorough inspections, checking for any defects or issues that may compromise the safety of the vehicle or equipment. Their role is crucial in promoting safety and preventing accidents in the automotive industry.

SEMA stands for Specialty Equipment Market Association. It is an organisation that supports the automotive aftermarket industry. They provide resources, networking opportunities, and advocacy for businesses in this sector. The association hosts an annual trade show in Las Vegas, showcasing the latest products and innovations in the automotive industry. SEMA also offers an inspector program to ensure that businesses meet industry standards for quality and safety. So, if you’re wondering, it represents an essential organisation in the automotive aftermarket industry.

SEMA Inspectors have a vital role in ensuring safety and compliance in various industries. They conduct inspections and audits, provide training and guidance, and play a crucial part in maintaining safety regulations. Their main objective is to help organizations adhere to safety protocols, preventing accidents and ensuring a secure working environment. This section explores the responsibilities and significance of SEMA Inspectors, emphasizing their dedication to workplace safety.

By diligently carrying out these steps, SEMA inspectors contribute to creating a safe work environment and reducing the risk of accidents and legal consequences. Ensuring compliance with safety regulations is essential for protecting employees and promoting a culture of safety in businesses.

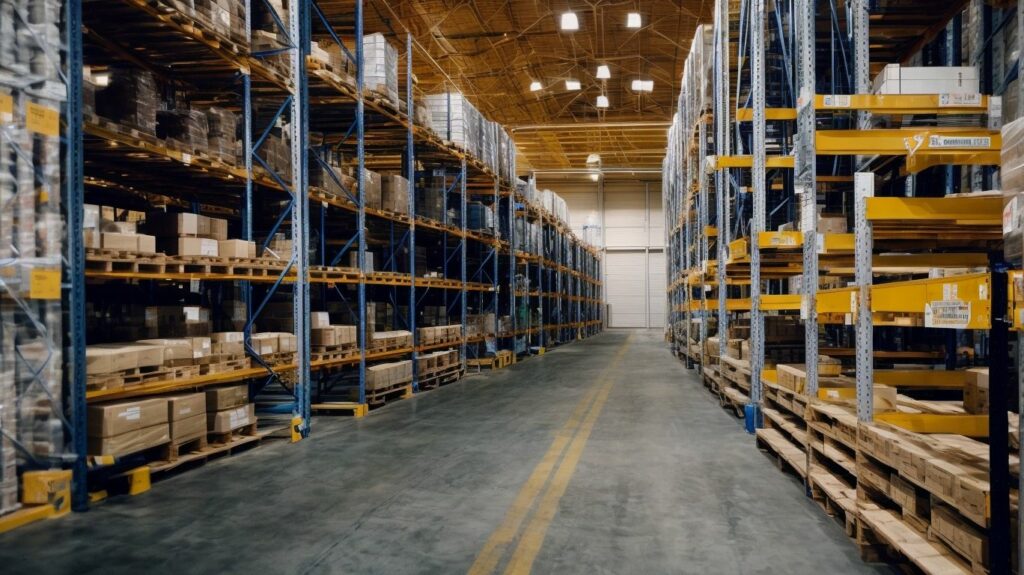

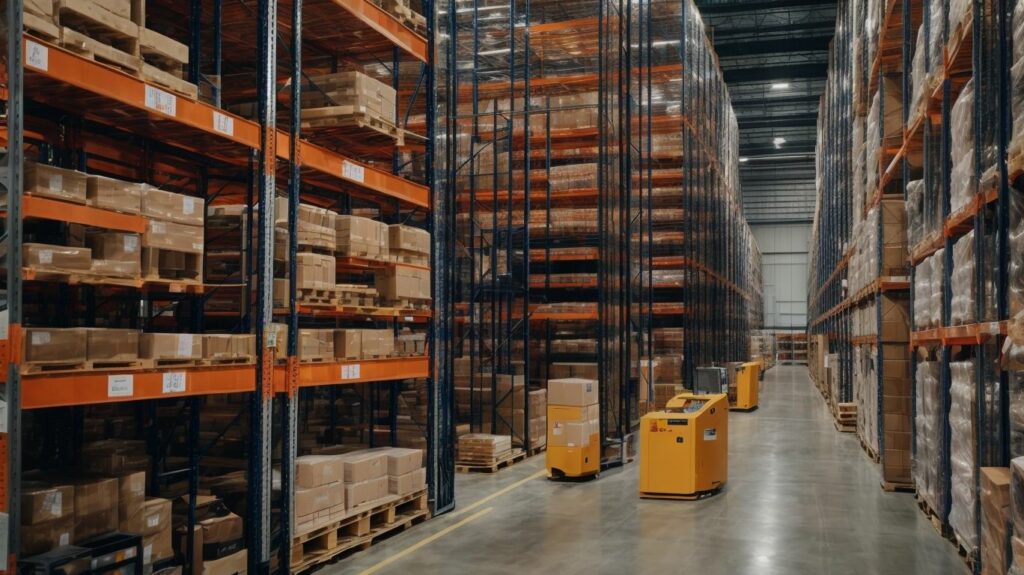

Conducting inspections and audits is a vital responsibility of SEMA inspectors. They ensure compliance with safety regulations, identify potential hazards, and promote a safe working environment. The following steps are involved in conducting inspections and audits:

Through conducting thorough inspections and audits, SEMA inspectors have a crucial role in preventing workplace accidents and ensuring compliance with safety regulations.

Providing training and guidance is a crucial role of SEMA inspectors in promoting workplace safety and compliance. They offer expertise and support to businesses in implementing safety measures and procedures. Here are the steps they take to provide effective training and guidance:

By providing comprehensive training and guidance, SEMA inspectors contribute to creating a safe work environment, reducing accidents, and ensuring compliance with safety regulations. Employers can enhance workplace safety by actively engaging with SEMA inspectors and implementing their recommendations.

To become a SEMA inspector, you need dedication and a specific set of skills. Here is a step-by-step guide on how to become a SEMA inspector:

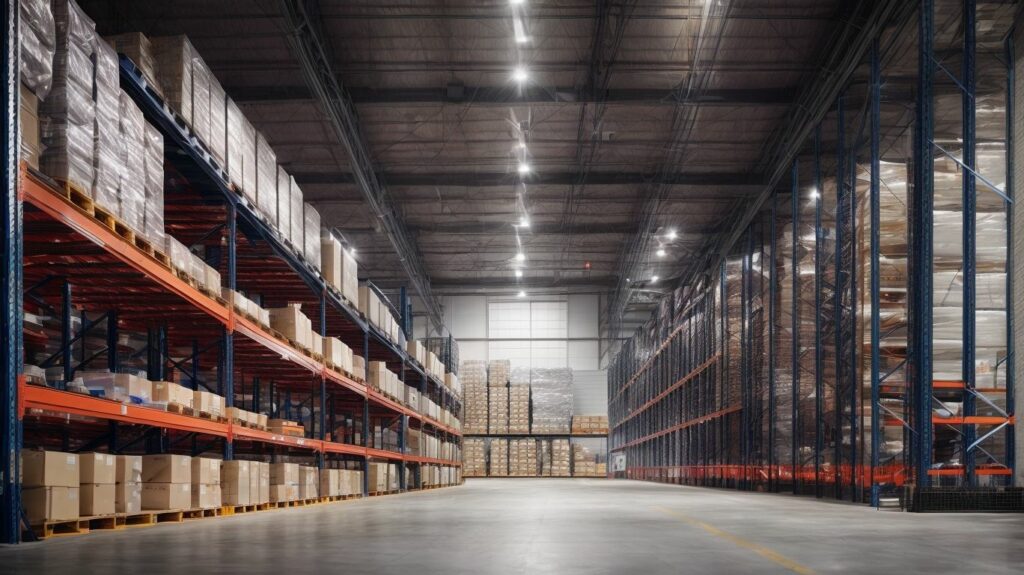

SEMA inspections are important for businesses as they play a crucial role in safeguarding the business, ensuring warehouse safety, reducing workplace accidents and avoiding legal consequences. These inspections aim to create a secure environment, bringing peace of mind to both employers and employees. By following SEMA guidelines, businesses can proactively address potential hazards and maintain regulatory compliance.

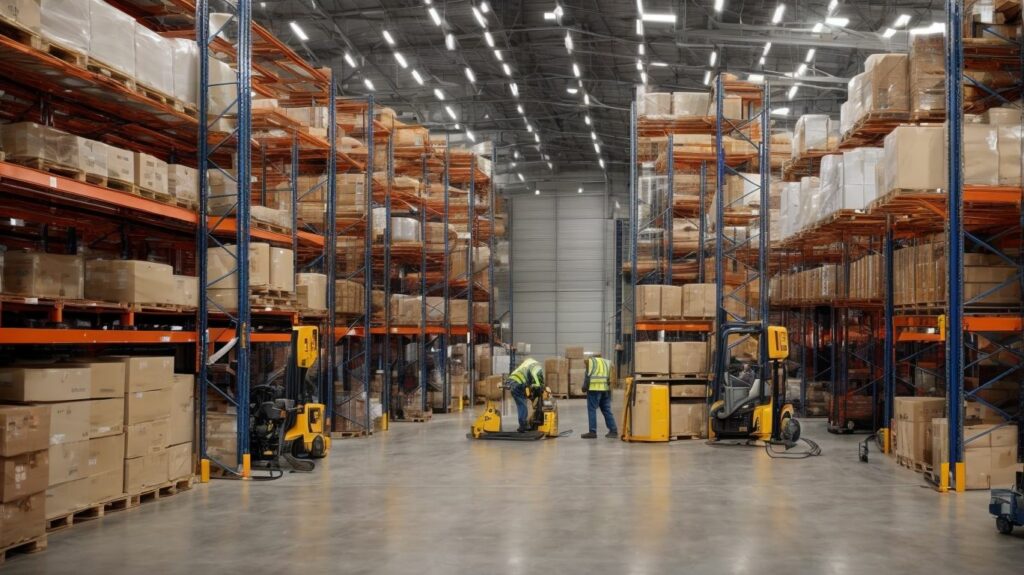

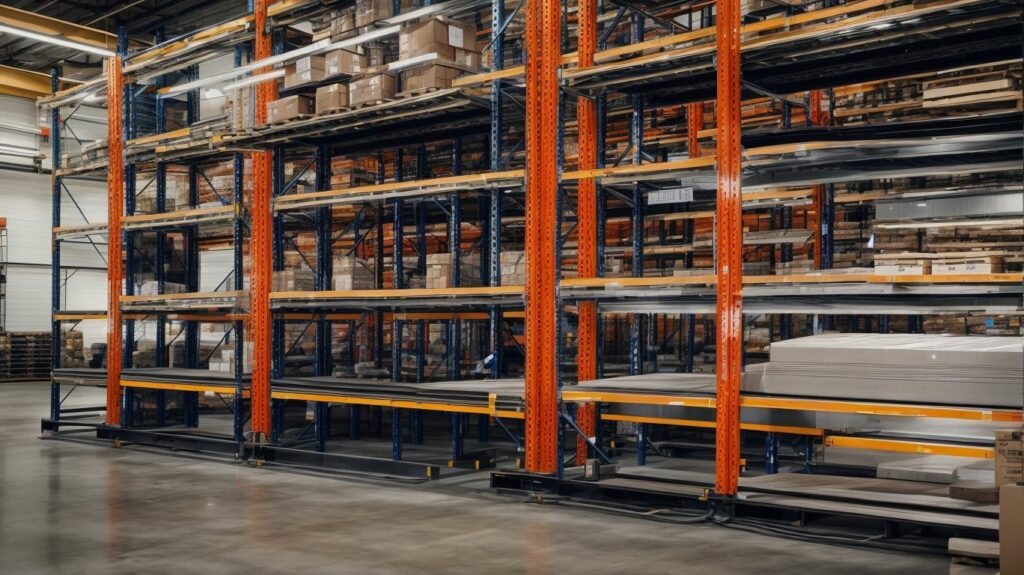

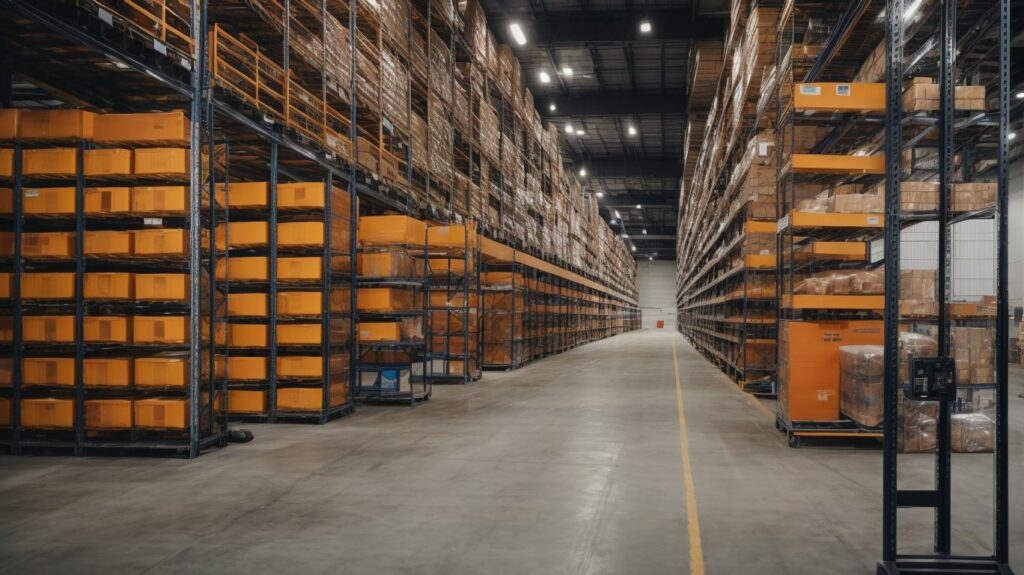

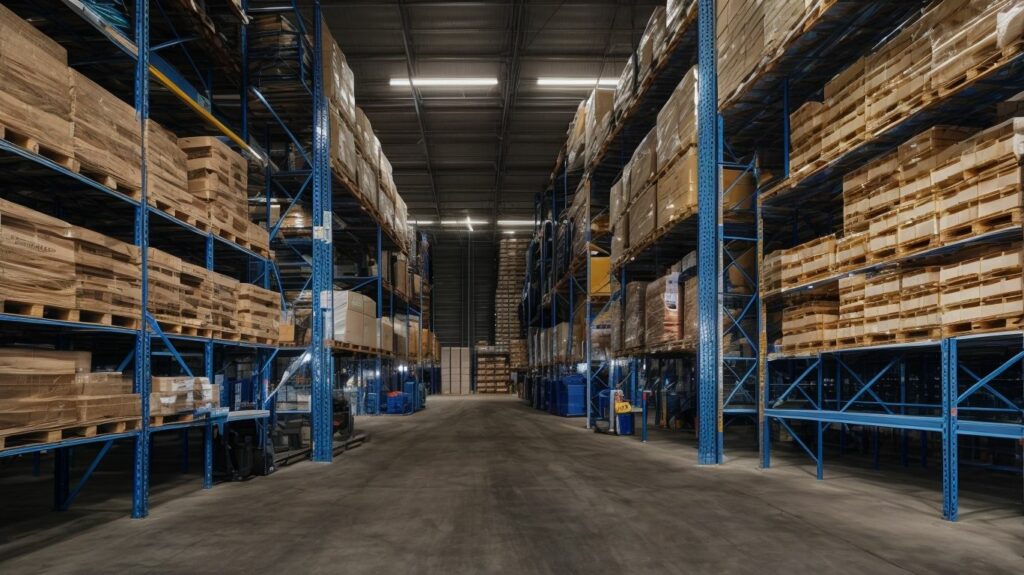

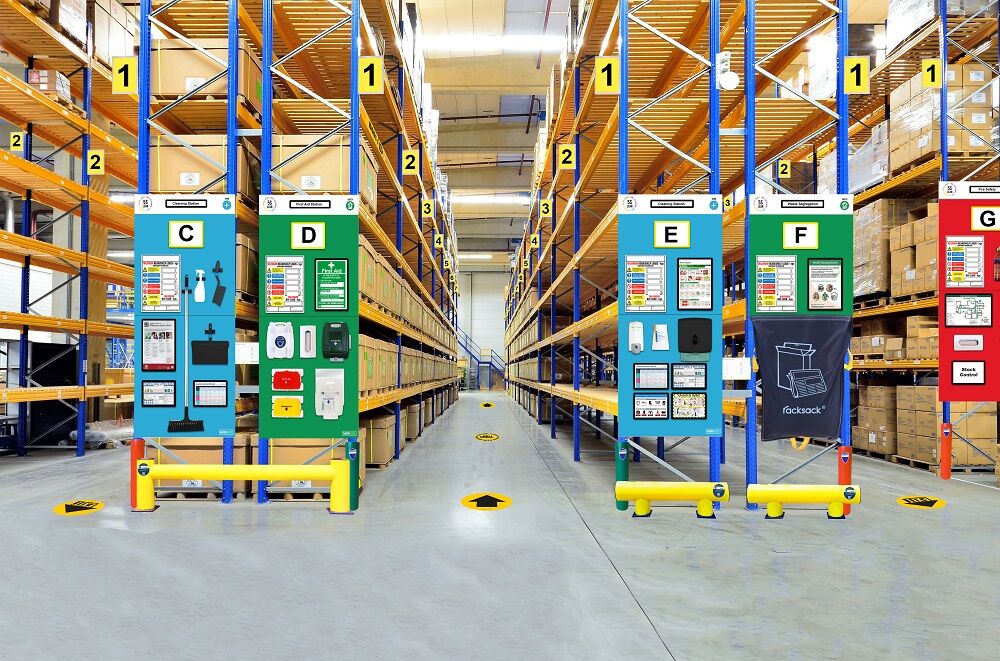

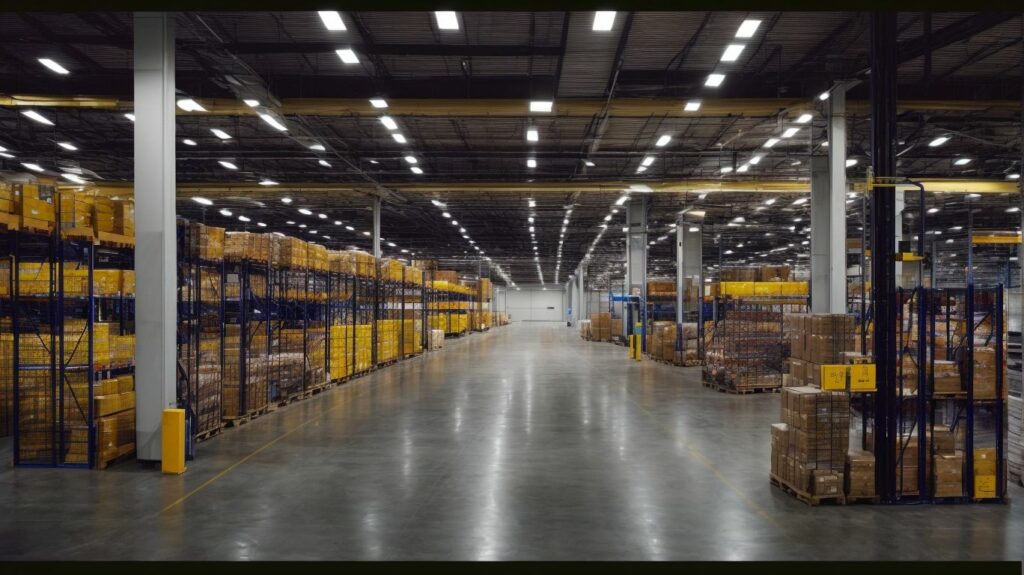

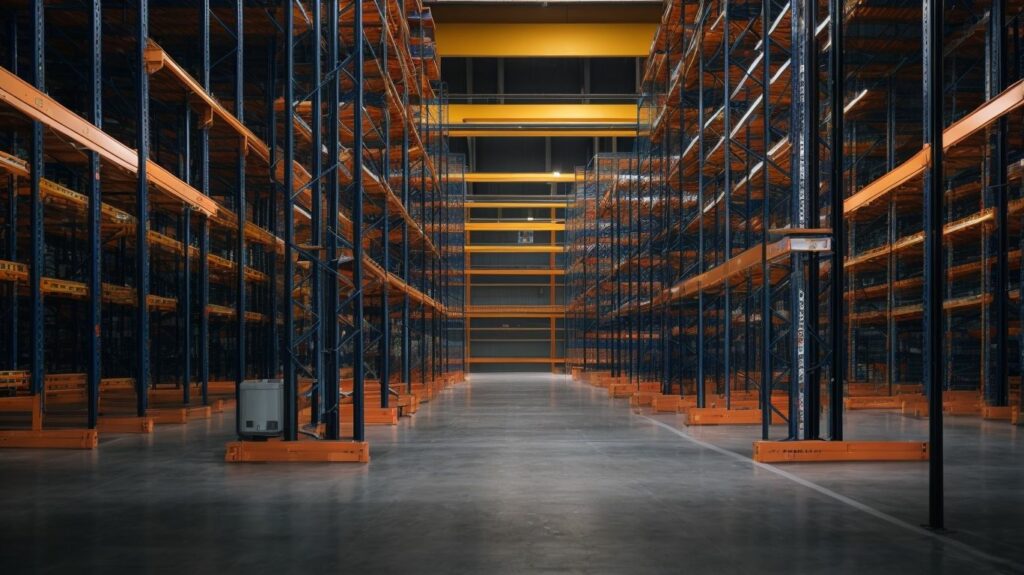

Ensuring warehouse safety is vital for businesses in order to prevent accidents, protect employees, and comply with regulations. Here are some steps that can be taken to prioritise warehouse safety:

Over time, warehouse safety has improved due to the establishment of safety standards and regulations, increased awareness of workplace hazards, and advancements in technology and safety equipment.

Reducing workplace accidents is a crucial goal for businesses, and SEMA inspections play a vital role in achieving this. Here are some steps to reduce workplace accidents:

Fact: According to the Health and Safety Executive (HSE), businesses that prioritise safety and have effective accident prevention strategies experience fewer workplace accidents.

| Original Text | Translated Text |

|---|---|

| Reducing workplace accidents is a crucial goal for businesses, and SEMA inspections play a vital role in achieving this. Here are some steps to reduce workplace accidents: | Reducing workplace accidents is a crucial goal for businesses, and SEMA inspections play a vital role in achieving this. Here are some steps to reduce workplace accidents: |

| Fact: According to the Health and Safety Executive (HSE), businesses that prioritise safety and have effective accident prevention strategies experience fewer workplace accidents. | Fact: According to the Health and Safety Executive (HSE), businesses that prioritise safety and have effective accident prevention strategies experience fewer workplace accidents. |

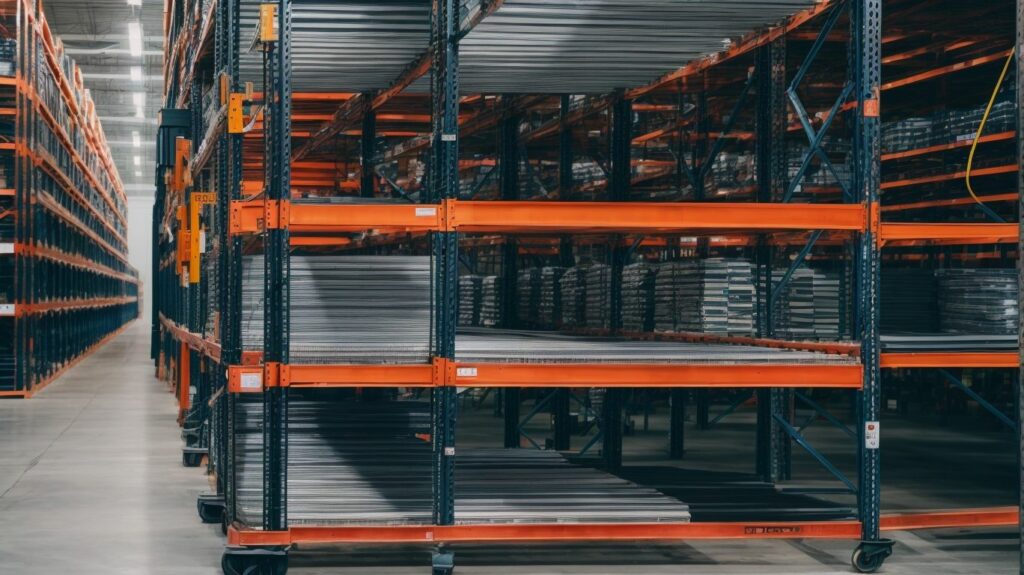

Avoiding legal consequences is a crucial aspect of SEMA inspections. SEMA inspectors play a vital role in ensuring that businesses comply with safety regulations to avoid legal issues. By conducting regular inspections and audits, SEMA inspectors identify potential hazards and non-compliance. This proactive approach helps businesses address safety concerns before accidents occur, reducing the risk of legal consequences such as lawsuits, fines, or penalties. A good SEMA inspector possesses knowledge of safety regulations, pays attention to detail, and has excellent communication skills to effectively convey safety guidelines and recommendations to businesses. By avoiding legal consequences, SEMA inspections contribute to maintaining a safe working environment.

SEMA Inspectors play a vital role in ensuring that safety standards are met. So, what are the qualities of a good SEMA Inspector? The qualities include their knowledge of safety regulations, attention to detail, and communication skills. They are well-versed in the regulations that protect both workers and customers. With a keen eye for detail, they thoroughly inspect storage systems. Their effective communication skills enable them to clearly convey their findings and recommendations. A good SEMA Inspector embodies expertise, precision, and effective communication.

To become a SEMA inspector, it is essential to have a deep understanding of safety regulations. Inspectors must be knowledgeable about laws and guidelines related to warehouse safety and workplace hazards. They should be familiar with industry-specific regulations and standards to ensure compliance. A good SEMA inspector should stay up to date with changes in safety regulations and be able to interpret and apply them effectively during inspections. It is recommended to continuously enhance your knowledge of safety regulations by attending workshops, seminars, and training programs to stay current with best practices and guidelines.

Having attention to detail is crucial for SEMA inspectors as they play a vital role in ensuring warehouse safety and reducing workplace accidents. Here are some reasons why attention to detail is important for SEMA inspectors:

Good communication skills are crucial for SEMA inspectors to effectively carry out their roles. Here are some key reasons why communication skills are important in this field:

Clear Instructions: Inspectors need to clearly communicate safety regulations and guidelines to businesses and employees to ensure understanding and compliance.

Effective Training: Inspectors should be able to deliver training programmes and provide guidance in a way that is easy to understand and engage with.

Active Listening: Being able to actively listen and understand any concerns or questions from businesses or employees is crucial in addressing their needs.

Interdepartmental Collaboration: Inspectors often work with other departments, such as health and safety or legal teams, and effective communication helps in coordinating efforts.

Pro-tip: Good communication skills not only enhance inspector efficiency but also foster a positive safety culture within businesses.

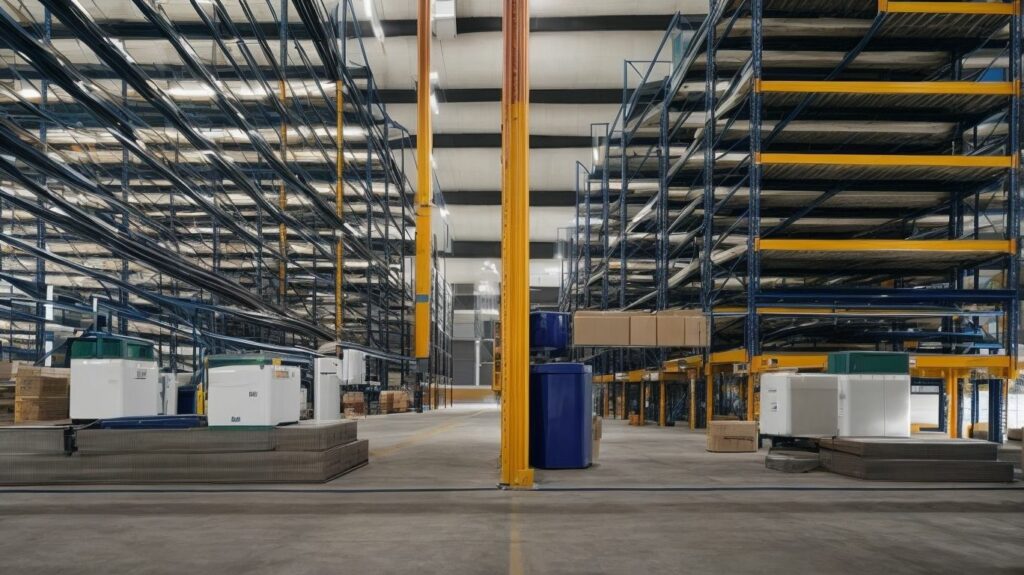

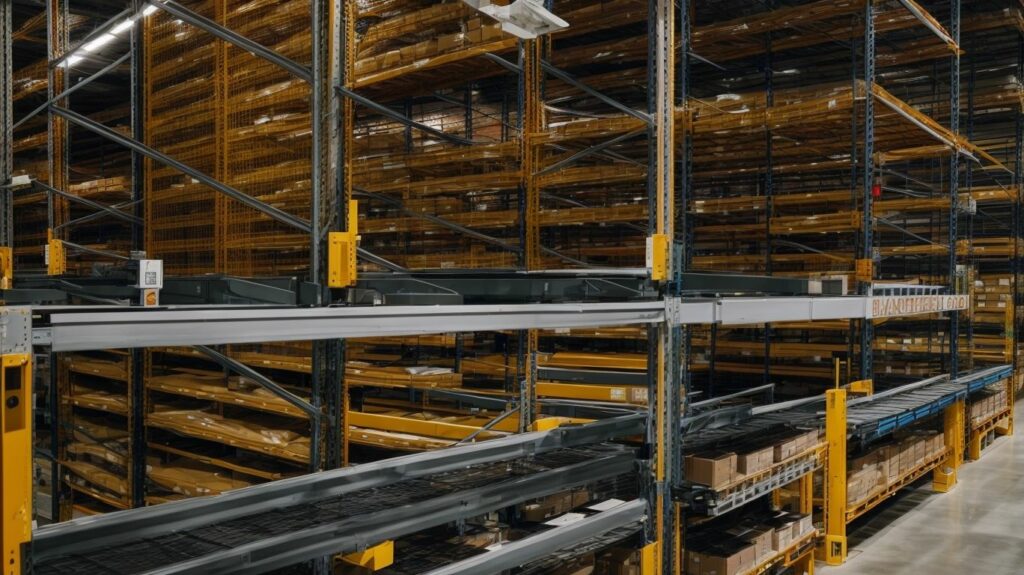

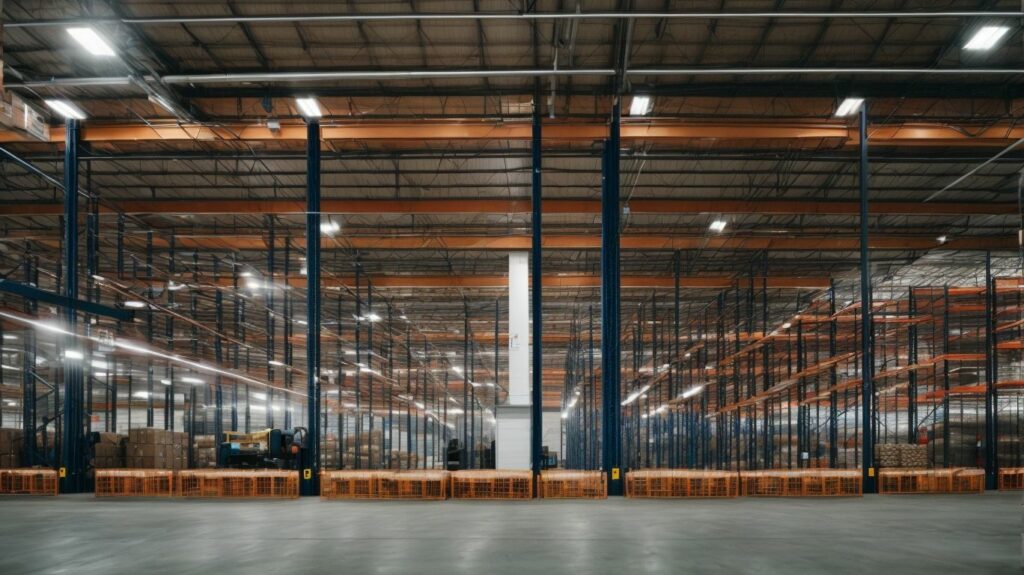

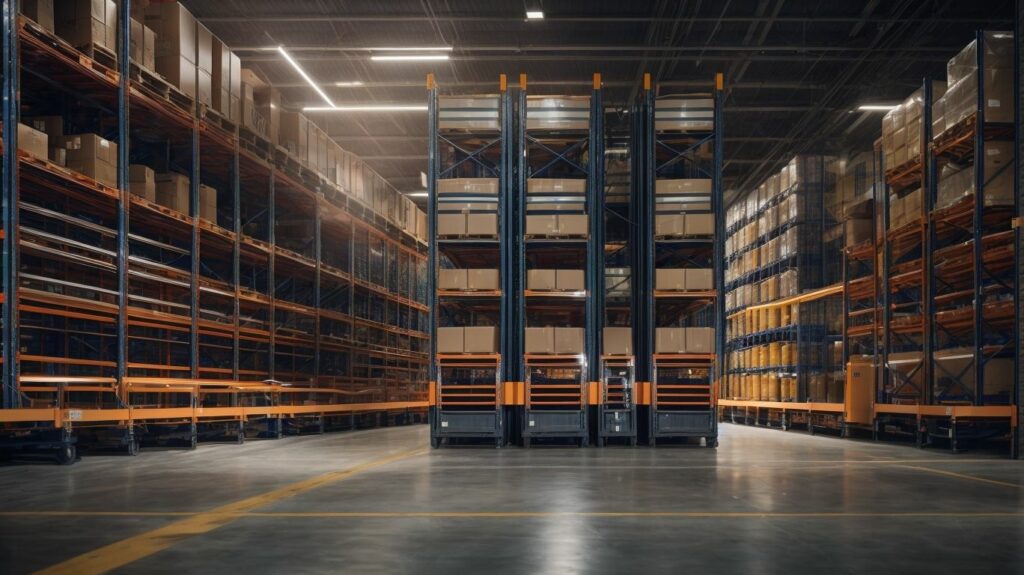

A SEMA Approved Rack Inspector (SARI) is a highly qualified professional who conducts inspections of racking and storage systems. They have undergone rigorous training and keep their knowledge up to date annually.

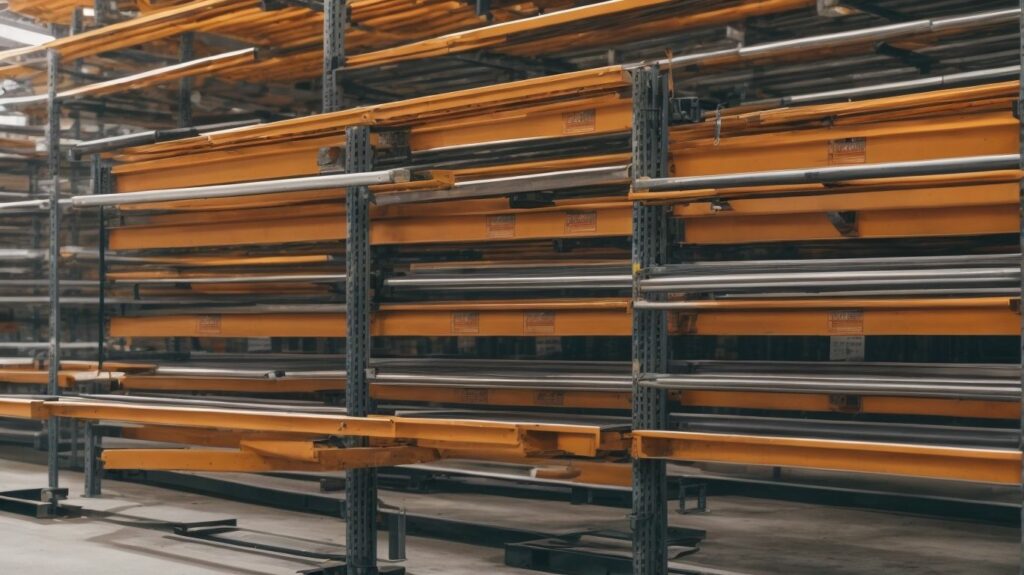

Regular pallet racking inspections are important as they are classified as work equipment and require expert inspections at least once a year. Failing to have regular inspections can lead to non-compliance with health and safety legislation and may invalidate insurance.

There are two types of annual inspections available: a full SARI inspection and a damage-only inspection. A full SARI inspection offers more comprehensive information, including immediate and regular scrutiny, rack configuration, and other safety-related matters.

The person responsible for rack safety, known as a PRRS, should be appointed in a warehouse. They ensure compliance with legal requirements and oversee the inspection, maintenance, and repair of racks.

According to the Health & Safety Executive guide HSG76 and SEMA guidelines, pallet racking is classified as work equipment and requires regular inspections. These inspections are necessary to ensure the equipment’s condition, compliance with health and safety regulations, and the safe use of racks.

Rack inspections should be conducted by a qualified SARI or another technically competent person. Qualified SARIs have the expertise and knowledge to identify potential risks, assess the condition of racking, and provide recommendations to ensure a safe environment.

We Aim To Reply To All Enquiries With-in 24-Hours