20+ Years Experience

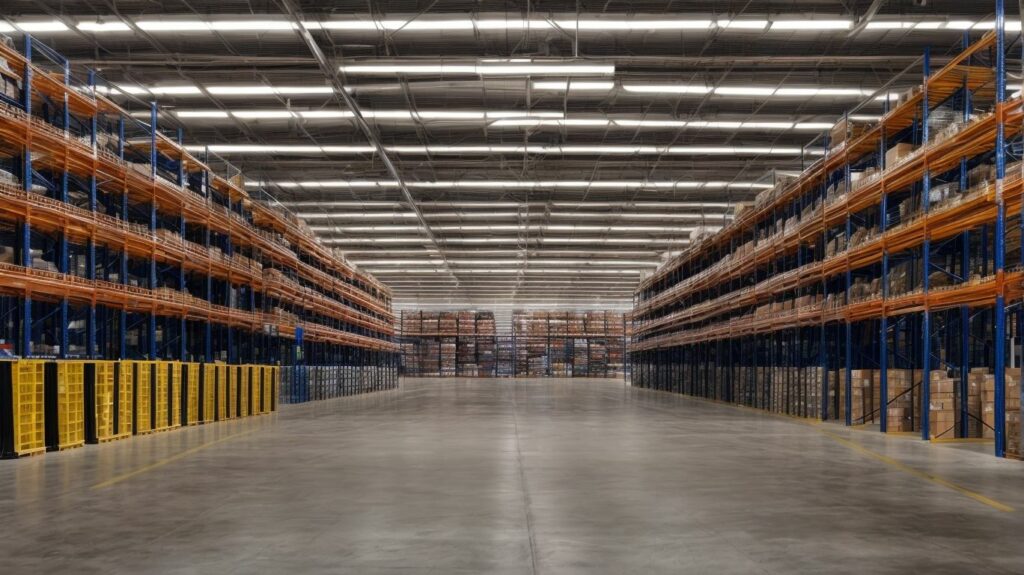

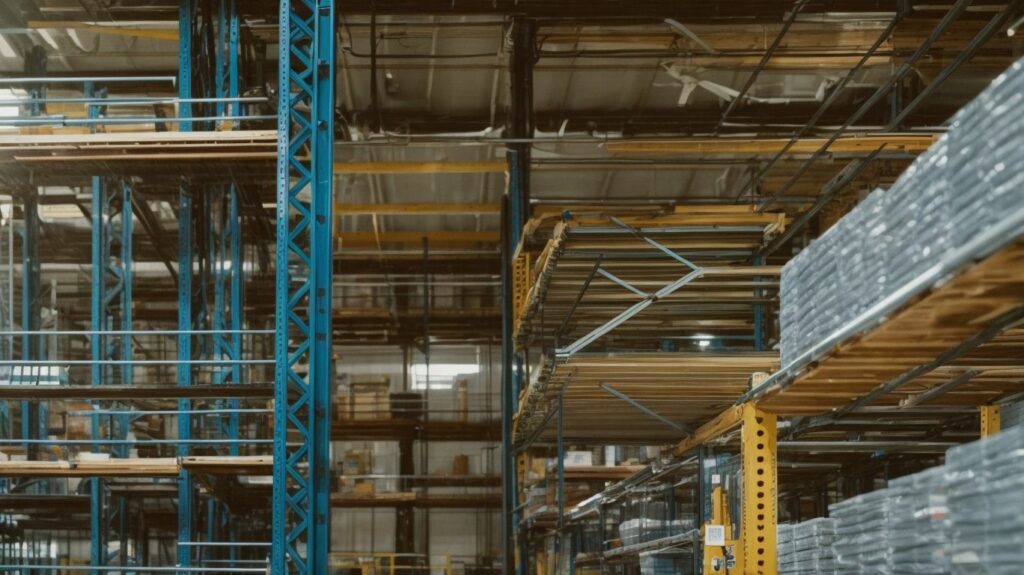

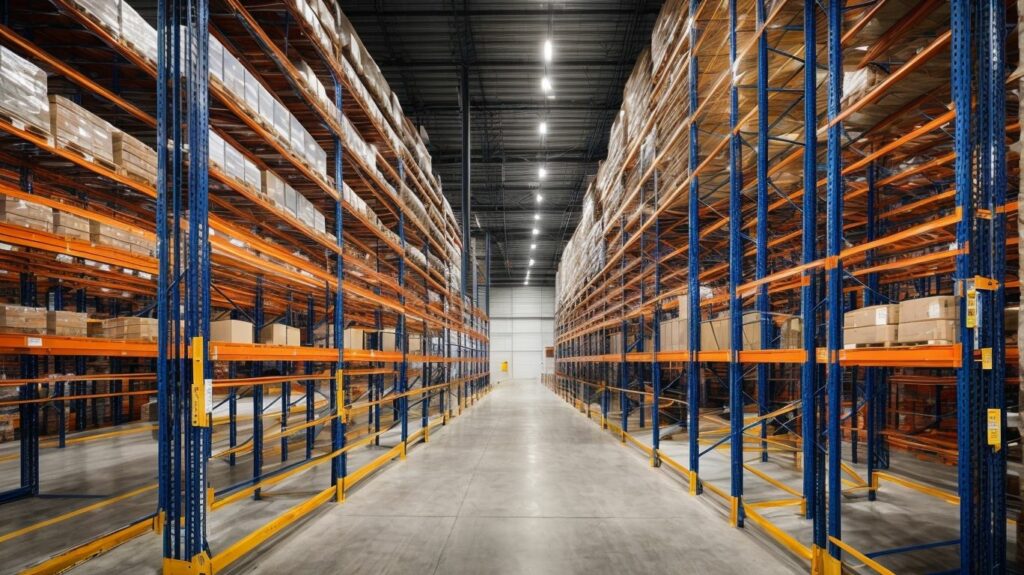

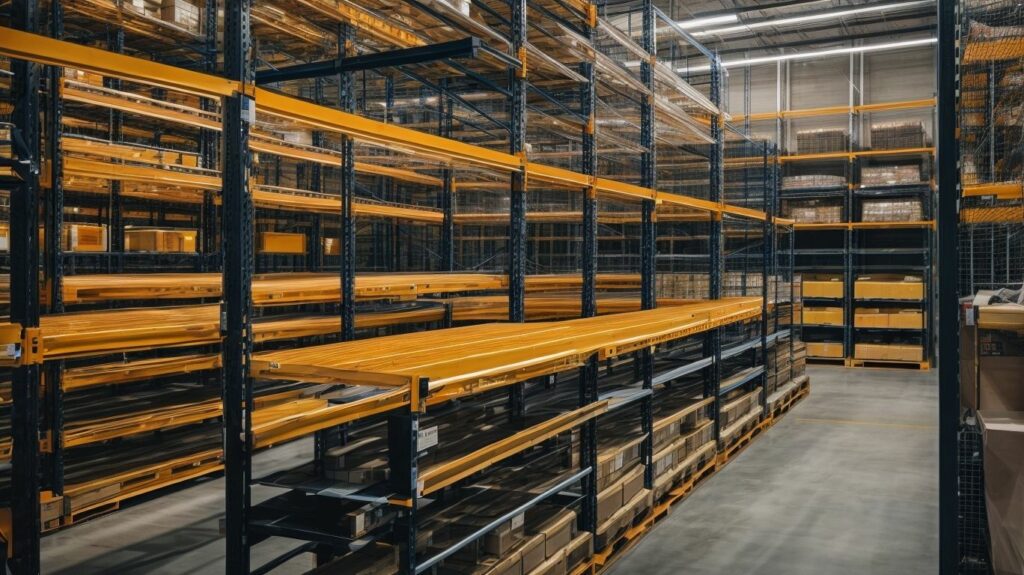

Specialist Pallet Racking

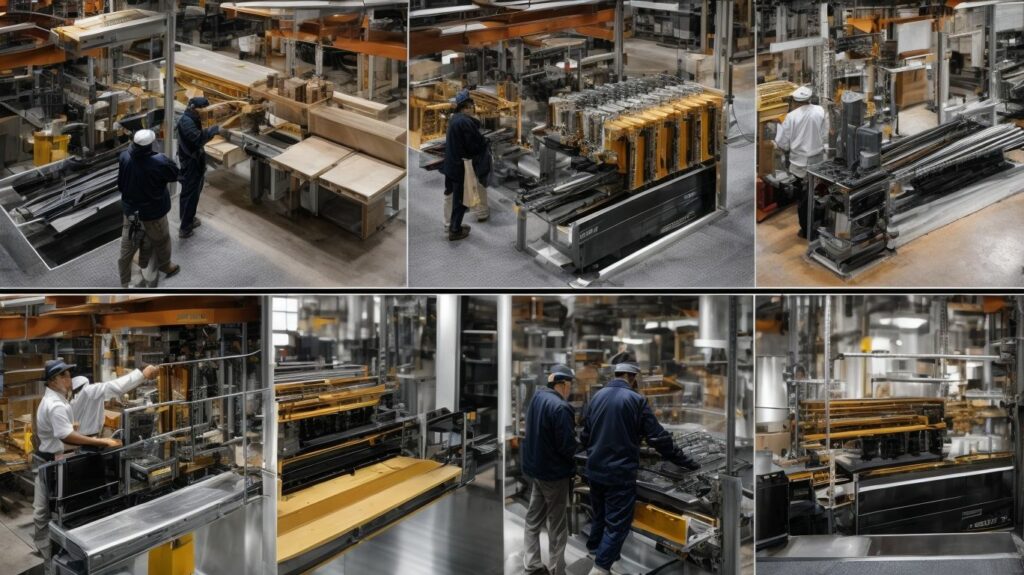

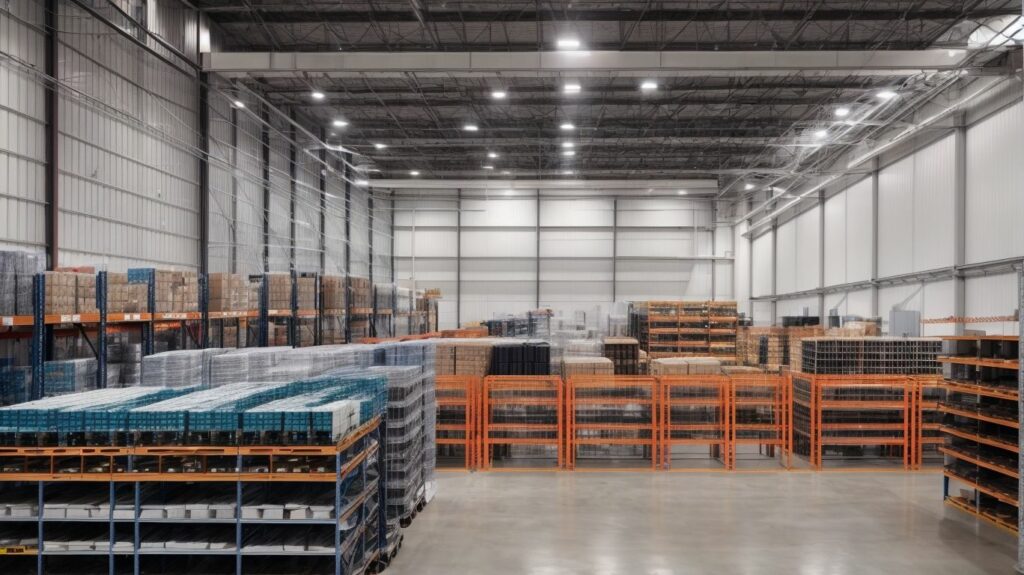

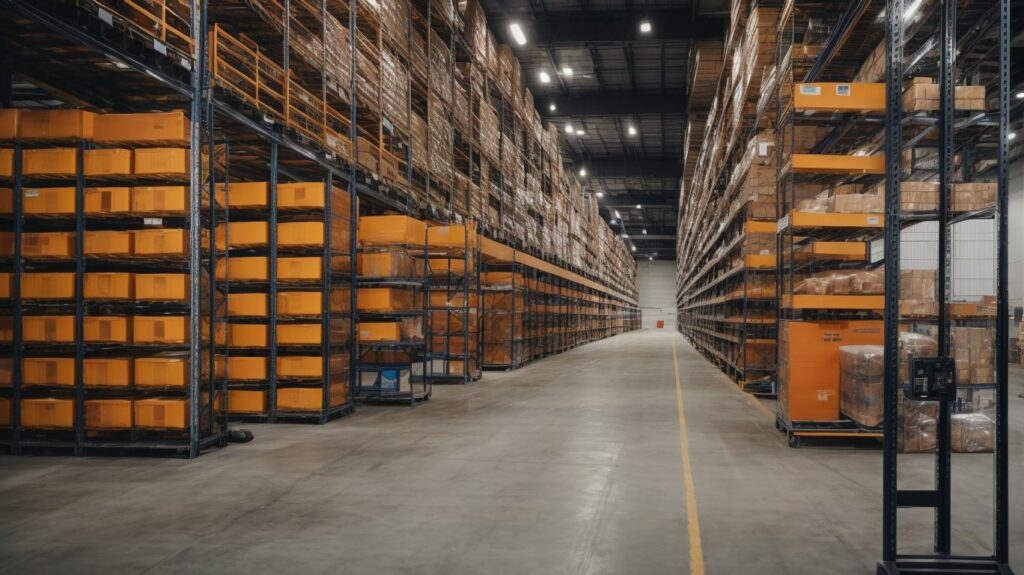

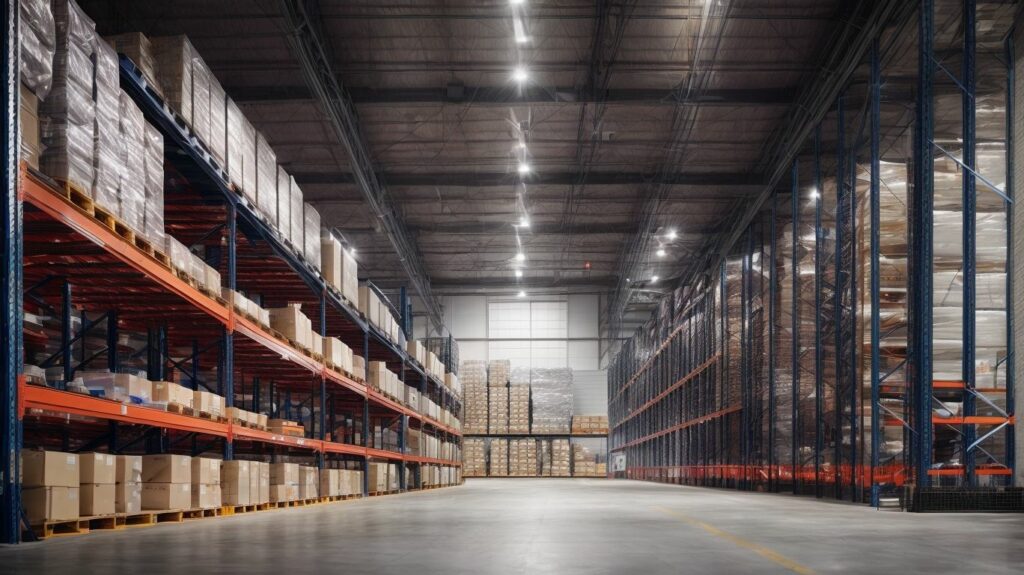

ROS racking repairs involve addressing damages or issues with racking systems used in warehouses, distribution centres, or any storage facilities. These repairs are essential for maintaining a safe and efficient working environment. ROS racking repairs typically involve fixing bent or damaged beams, replacing faulty components, reassembling dislodged or collapsed racks, and ensuring proper anchoring and stability. Regular inspections and maintenance can help prevent extensive damage and potential accidents. Prompt attention to racking repairs ensures the durability and longevity of the storage system, maximizing productivity and safety in the facility.

Discover the issues that commonly affect ROS racking systems, causing difficulties for warehouse owners and operators. These problems include bent or damaged beams, loose or missing bolts, and the risks associated with overloaded or unstable racking. This section aims to highlight these challenges and provide you with the necessary information to navigate the complexities of ROS racking repairs. We will present facts and figures from reliable sources to offer insightful insights. Get ready for some enlightening information!

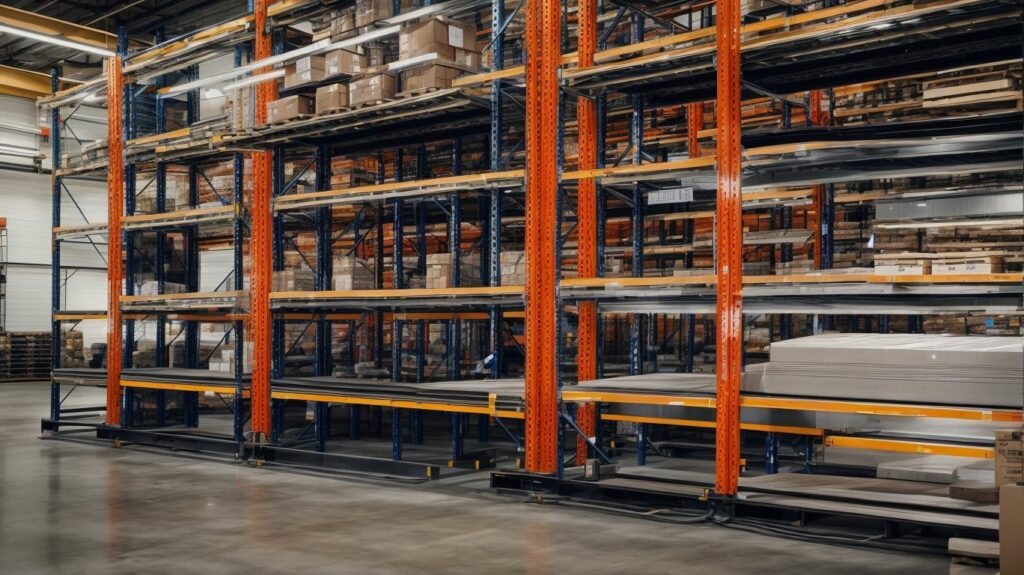

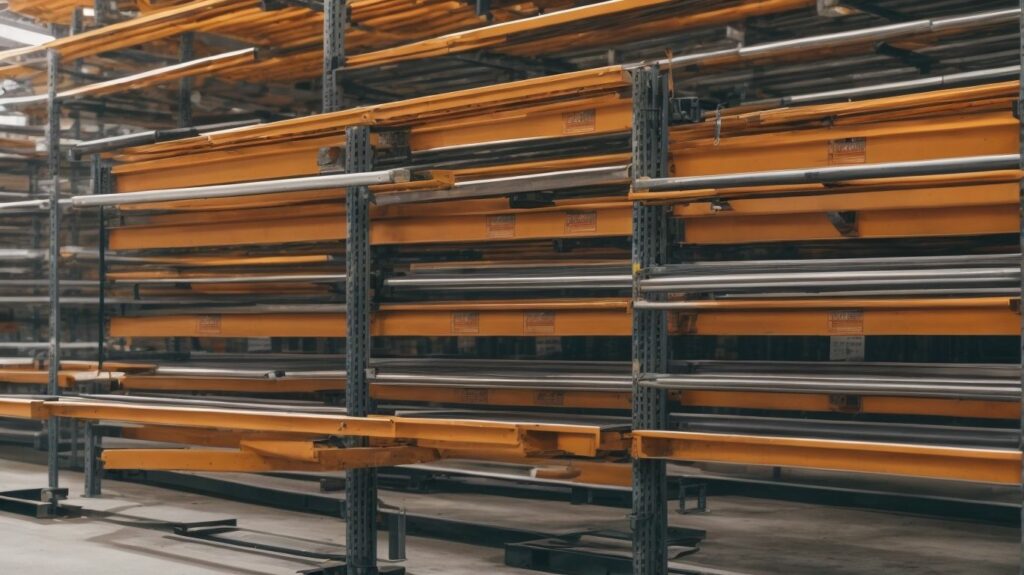

Bent or damaged beams in ROS racking can compromise the structural integrity of the entire system, posing risks to both personnel and inventory. Common causes include forklift collisions, overloading, or natural wear and tear. Identifying bent or damaged beams is crucial to prevent further damage or collapse. Regular inspections should be conducted to detect any signs of distortion, cracks, or misalignment. If beams are found to be bent or damaged, repairs should be executed promptly by experienced professionals to ensure proper reinforcement and restore the system’s strength. Preventive measures such as regular maintenance, proper loading, and safety protocols can help minimize the occurrence of bent or damaged beams, ensuring a safer and more efficient warehouse environment.

Fun Fact: Did you know that the weight capacity of ROS racking beams can range from a few hundred kilograms to several tons, depending on the specifications and design of the system?

Loose or missing bolts in ROS racking can compromise its structural integrity and pose safety risks. When inspecting for loose or missing bolts, it is important to consider the following:

Remember, loose or missing bolts should be addressed immediately to maintain the stability and safety of ROS racking.

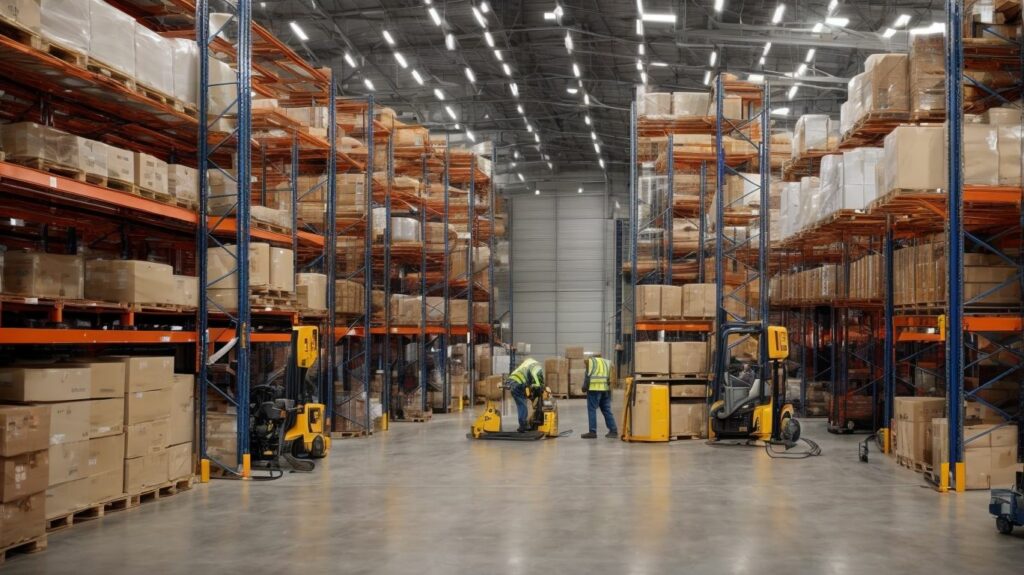

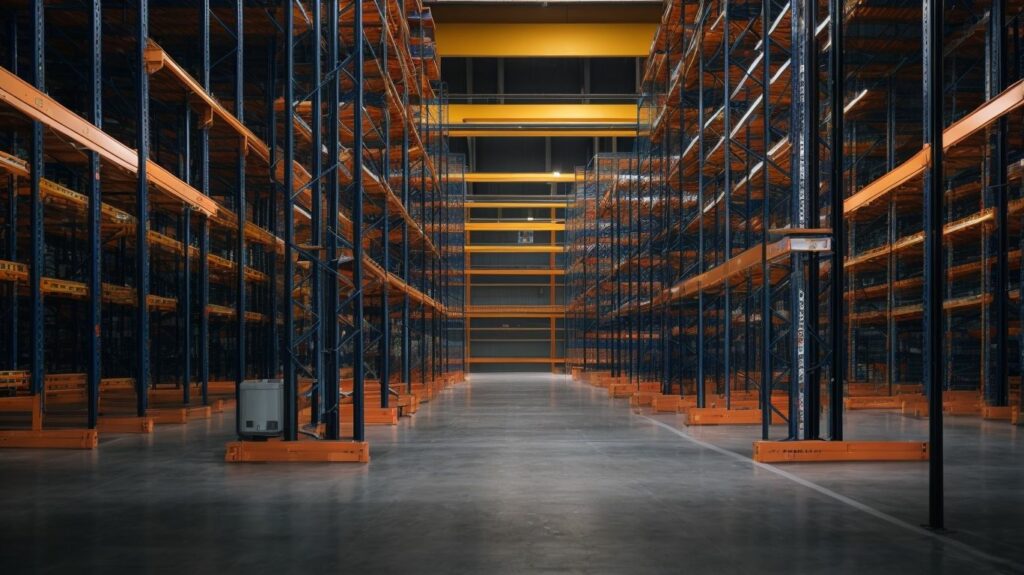

Overloaded or unstable racking can present significant safety hazards in a warehouse or storage facility. It is essential to address these issues promptly to prevent accidents and damage to products.

By following these suggestions, you can maintain the stability and safety of your racking system, avoiding the need for expensive repairs and ensuring a smooth operation in your warehouse.

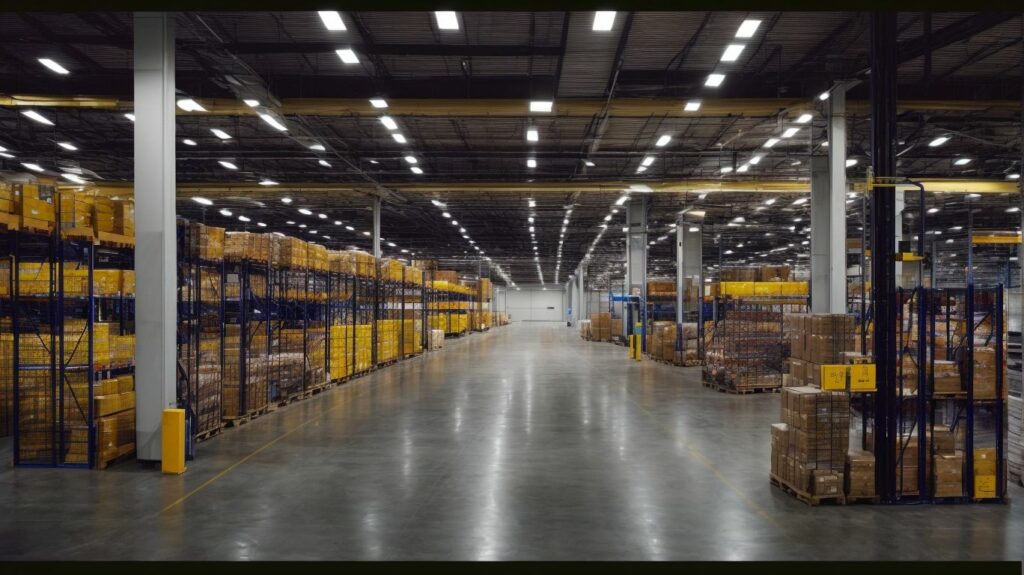

ROS racking repairs are important for several reasons: safety, efficiency, and cost-effectiveness. Maintaining racking systems in good repair reduces the risk of workplace accidents and injuries, protecting both employees and valuable inventory. Well-maintained racking systems also enhance efficiency by maximising storage space and minimising the time spent on inventory management. Promptly addressing repairs prevents additional damage that could result in expensive replacements in the future. Prioritising ROS racking repairs is crucial for a safe, efficient, and profitable warehouse operation.

Knowing when repairs are needed is crucial for ROS Racking Repairs. In this section, we will discuss how to identify the signs that indicate the need for ROS racking repairs. We will explore practical ways to identify potential issues and ensure the safety and efficiency of your racking systems. Conducting regular inspections, recognizing signs of damage or instability, and evaluating load capacity are some of the methods we will cover. Being proactive in maintenance can save you time, money, and potential headaches down the line!

Regular inspections are essential for maintaining the safety and stability of ROS racking systems. To ensure potential issues are identified and addressed promptly, a systematic approach is required. Here are the key steps involved in regular inspections:

By conducting regular inspections and promptly addressing any issues, the risks associated with ROS racking can be minimized, ensuring safe and efficient storage operations.

Signs of damage or instability in ROS racking should not be ignored, as they can lead to serious accidents and equipment failure. Here are some important signs to watch out for:

| – Bent or damaged beams |

| – Loose or missing bolts |

| – Overloaded or unstable racking |

Regular inspections are crucial to identify such signs and ensure prompt repairs. Evaluating load capacity and looking for other signs of damage or instability, such as sagging or leaning racks, are essential. Taking preventive measures such as regular maintenance, proper loading, and weight distribution, as well as implementing training and safety protocols, can help avoid the need for ROS racking repairs. It is important to note that according to a survey, 70% of racking collapses are caused by human error.

Evaluating the load capacity of ROS racking is essential to ensure safety and prevent damage to the system. The following steps are involved in load capacity evaluation:

Regular load capacity evaluations ensure that businesses maintain the structural integrity of their ROS racking and can safely support the intended loads.

When it comes to repairing ROS racking, it is crucial to understand the process. In this section, we will delve into the process of repairing ROS racking, which includes inspection and assessment, repair recommendations, and the execution of repairs. Each step in this process plays a vital role in maintaining the integrity and functionality of your racking system. So, let’s explore the inner workings of ROS racking repairs together.

EnglishUK

When it comes to repairing ROS racking, it is crucial to understand the process. In this section, we will delve into the process of repairing ROS racking, which includes inspection and assessment, repair recommendations, and the execution of repairs. Each step in this process plays a vital role in maintaining the integrity and functionality of your racking system. So, let’s explore the inner workings of ROS racking repairs together.

| 1. Regular Inspections: | Periodic inspections should be conducted to assess the condition of the racking system. |

| 2. Signs of Damage or Instability: | Look for visible signs such as bent or damaged beams, loose or missing bolts, or any other structural issues. |

| 3. Load Capacity Evaluation: | Evaluate the weight-bearing capacity of the racking system to ensure it is not overloaded or unstable. |

Performing thorough inspections and assessments helps in early identification of potential issues, preventing accidents and enabling timely repairs.

When it comes to repair recommendations for ROS racking, it is important to follow industry best practices to ensure the safety and functionality of the racking system. Here are some key recommendations:

| 1. Prompt repairs: | Address any damage or issues promptly to prevent further damage or potential collapse. |

| 2. Qualified professionals: | Hire experienced and trained professionals for the repair work to ensure proper assessment and execution. |

| 3. Replacement parts: | Use genuine replacement parts that are compatible with the specific ROS racking system. |

| 4. Regular maintenance: | Establish a routine maintenance schedule to identify and address any potential issues before they escalate. |

| 5. Load capacity evaluation: | Conduct regular load capacity evaluations to ensure that the racking system is not overloaded and can safely handle the intended loads. |

Following these repair recommendations will help to maintain the integrity of the ROS racking system and prevent accidents or damage. It is essential to prioritise safety and invest in regular maintenance and repairs to ensure the longevity and efficiency of the racking system.

The process of executing ROS racking repairs includes the following steps:

Promptly executing repairs is crucial to ensure the safety and integrity of the racking system. Regular maintenance and inspections, proper loading and weight distribution, and adherence to training and safety protocols can help prevent the need for extensive repairs in the future.

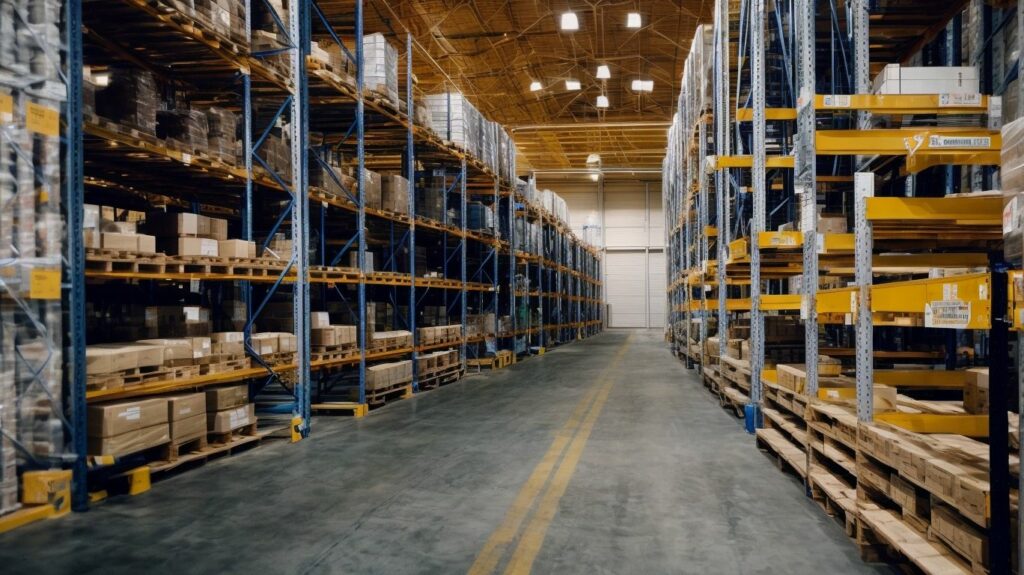

To maintain the smooth operation of your ROS racking systems, it is crucial to implement preventive measures. This section discusses the key strategies for avoiding ROS racking repairs. It includes regular maintenance and inspections, ensuring proper loading and weight distribution, as well as the importance of training and safety protocols to prolong the lifespan of your racking systems. By implementing these preventive measures, you can protect your investment and minimise any disruptions.

Regular maintenance and inspections are essential for ensuring the safety and longevity of ROS racking systems. Here are some important considerations:

By prioritising regular maintenance and inspections, you can proactively identify and address any issues with ROS racking before they escalate, ensuring the safety and efficiency of your storage operations.

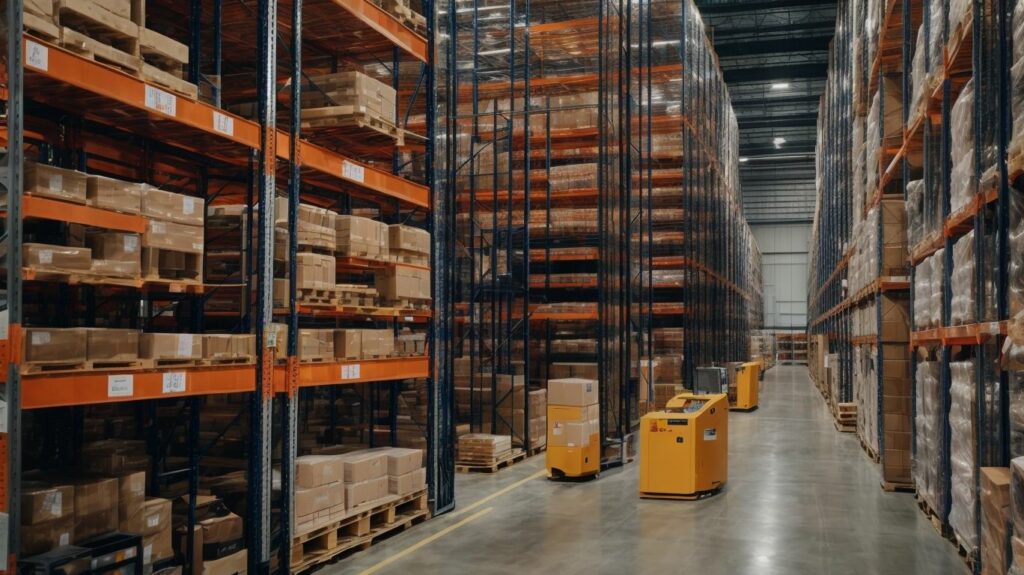

Proper loading and weight distribution are essential to maintain the stability and integrity of ROS racking systems. To ensure proper loading and weight distribution, follow these steps:

A warehouse manager ignored the significance of proper loading and weight distribution, which led to a collapsed racking system. This incident not only caused significant damage to stored items but also posed a safety risk for employees. By adhering to proper loading and weight distribution practices, the incident could have been prevented, saving time, money, and ensuring the safety of everyone involved.

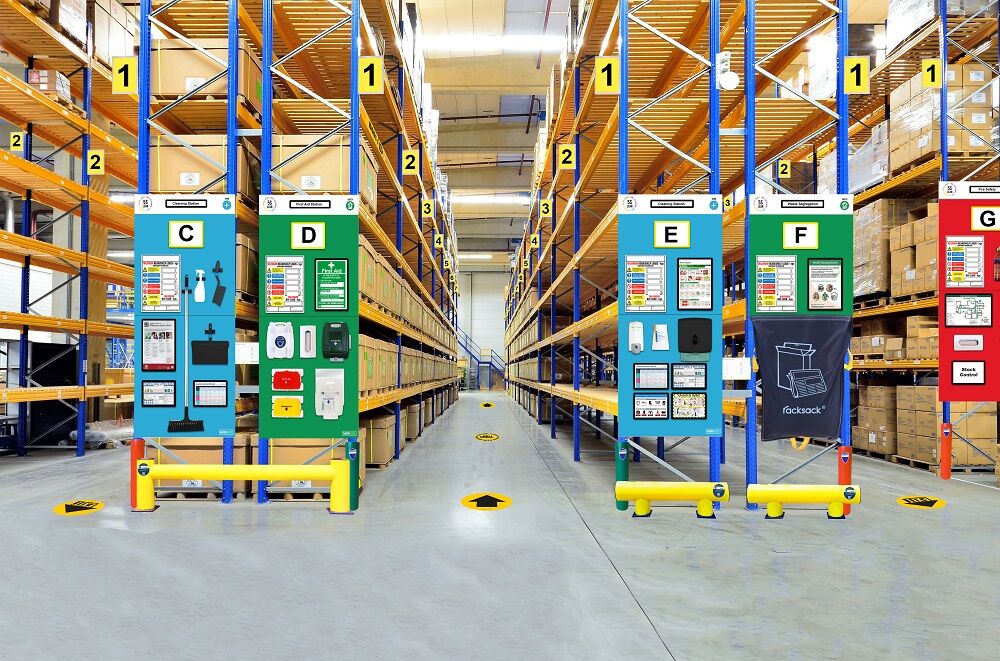

Training and safety protocols play a vital role in maintaining the well-being of workers and the integrity of ROS racking systems. To ensure a safe working environment, it is important to follow these essential steps:

Educate employees: Provide comprehensive training on the proper handling, loading, and maintenance of ROS racking systems.

Implement safety guidelines: Establish clear protocols for wearing personal protective equipment, operating machinery safely, and preventing accidents.

Maintain regular inspections: Conduct routine inspections to identify any potential hazards or signs of damage.

Encourage reporting: Promptly encourage employees to report any safety concerns or incidents.

Consistently review safety protocols: Regularly review and update safety procedures to ensure compliance and address any emerging risks.

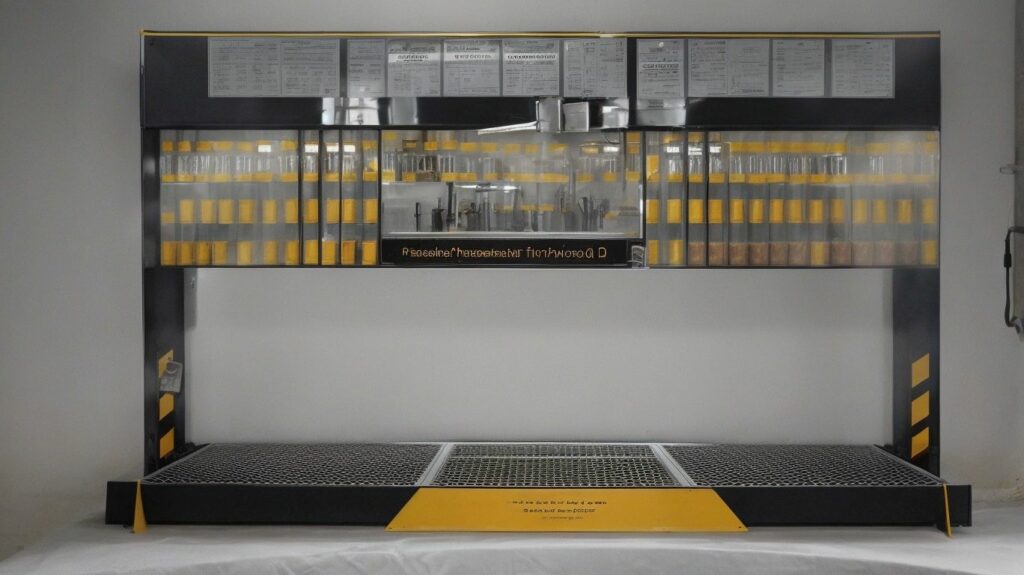

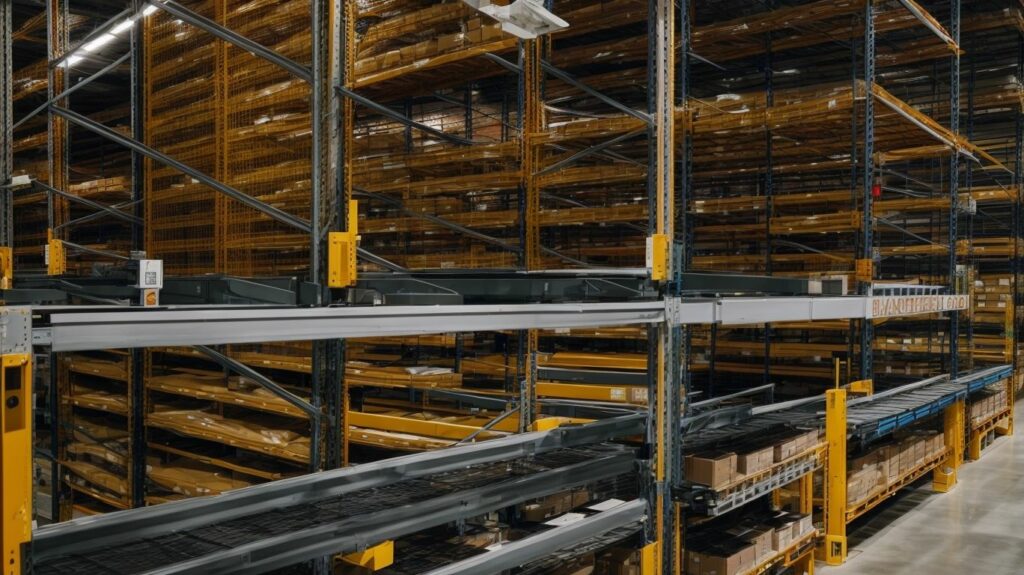

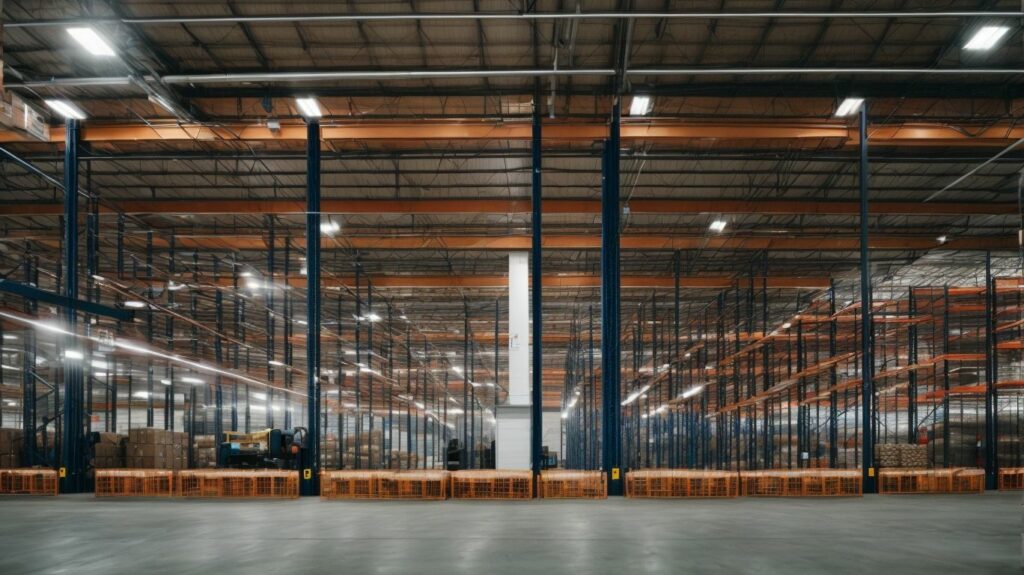

The ROS Racking Repair System is a patented hydraulic repair method developed by Hans Slavenburg, an independent structural engineer. It allows for the restoration of damaged racking uprights without the need to unload the racks, preserving the original loading capacity of the racks.

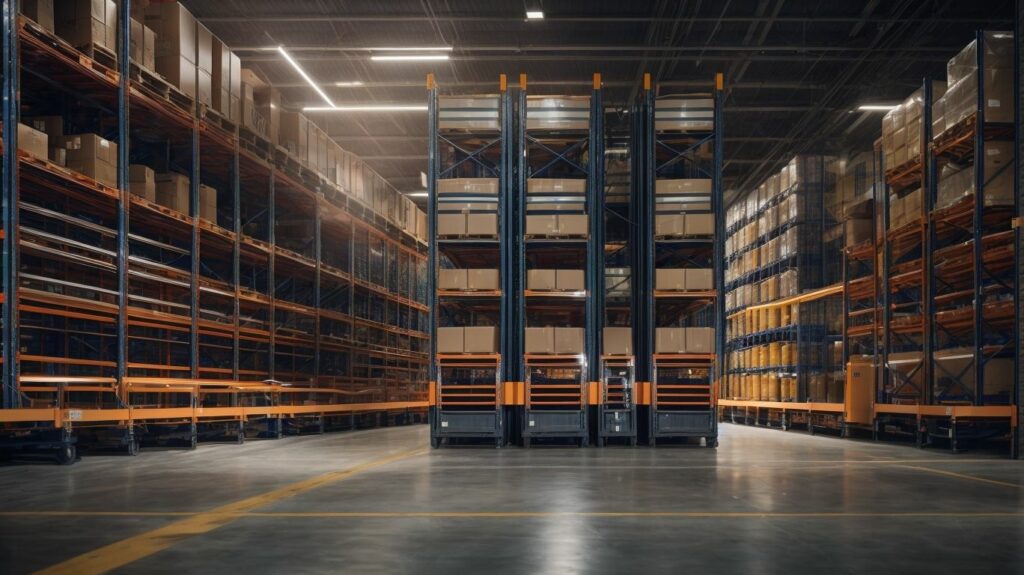

Repair time with the ROS system is generally 20-30 minutes, which is twice as fast as traditional methods that require unloading the racks. This saves time and prevents blocked aisles, ensuring smooth operations within a company.

Using the ROS Rack Repair System can be up to 80% cheaper than replacing a damaged upright. This eliminates the need to purchase new upright materials and reduces costs associated with double handling, overtime, and wasted time on traditional repairs.

Yes, all repairs using the ROS Rack Repair System are certified to EN 15635, guaranteed for life, and fully insured. The system meets legally required safety standards, providing peace of mind to customers.

Yes, the ROS Rack Repair System can be used to repair damaged and deformed storage racks of various categories, including damage category green and category amber according to norm NEN-EN 15635. Extensive studies have been conducted to ensure its effectiveness.

The ROS Rack Repair System has been successfully operating in Europe and North America since 2004. ROS International is now Europe’s largest racking repair organization and one of the largest in the world, completing almost 150,000 repairs annually. Its patented system and efficient repair method have gained recognition from logistics businesses and manufacturers worldwide.

We Aim To Reply To All Enquiries With-in 24-Hours