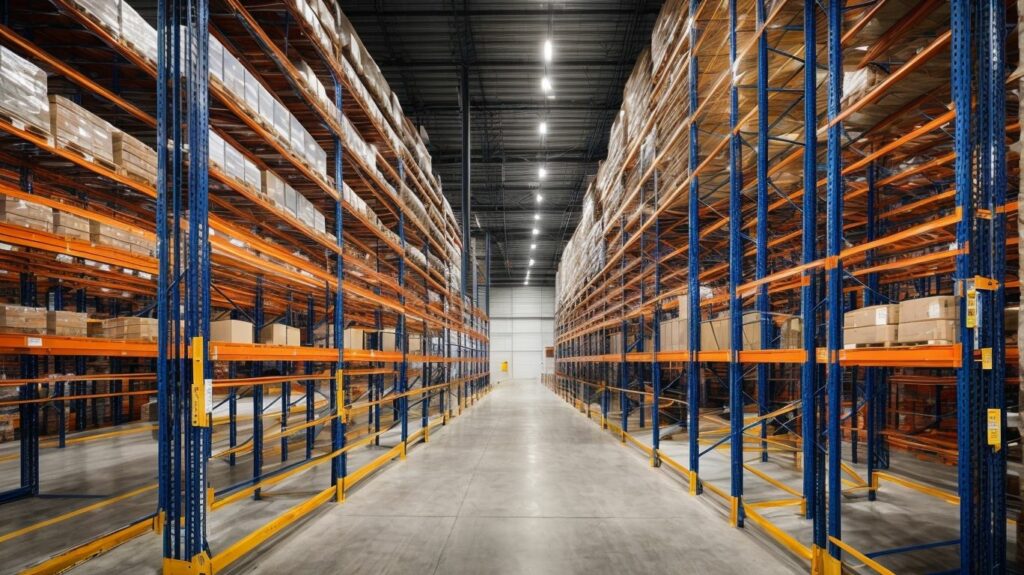

20+ Years Experience

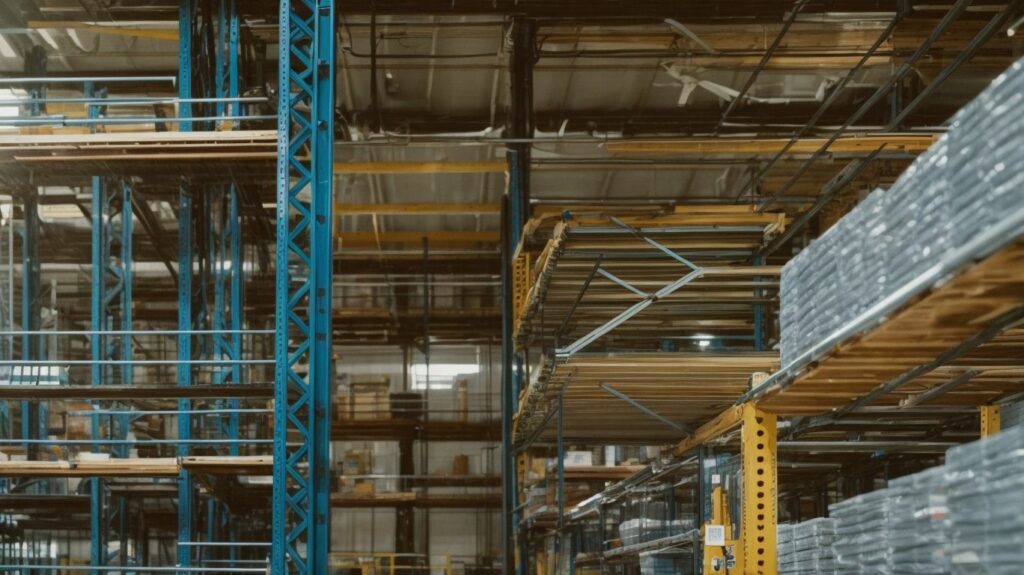

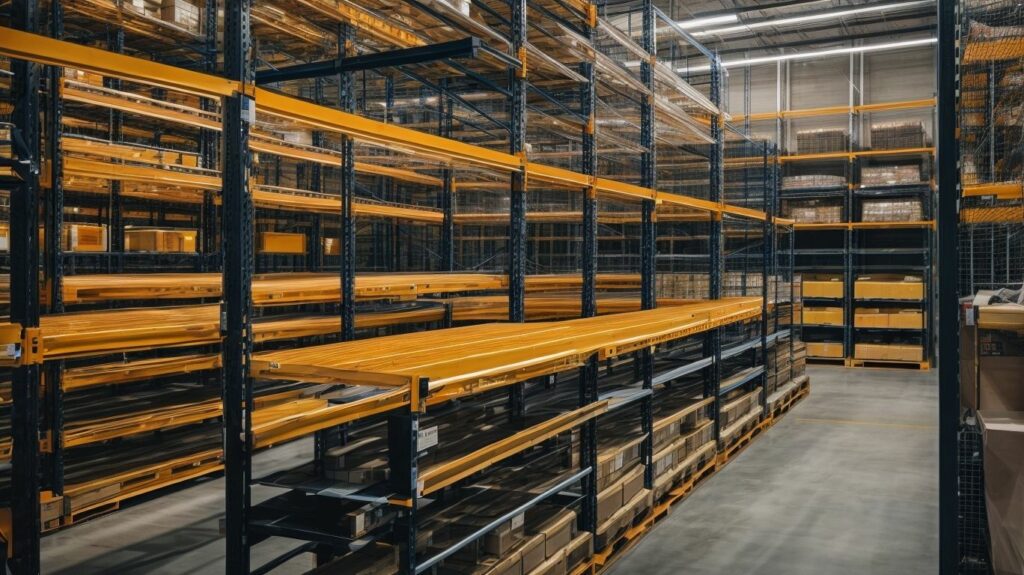

Specialist Pallet Racking

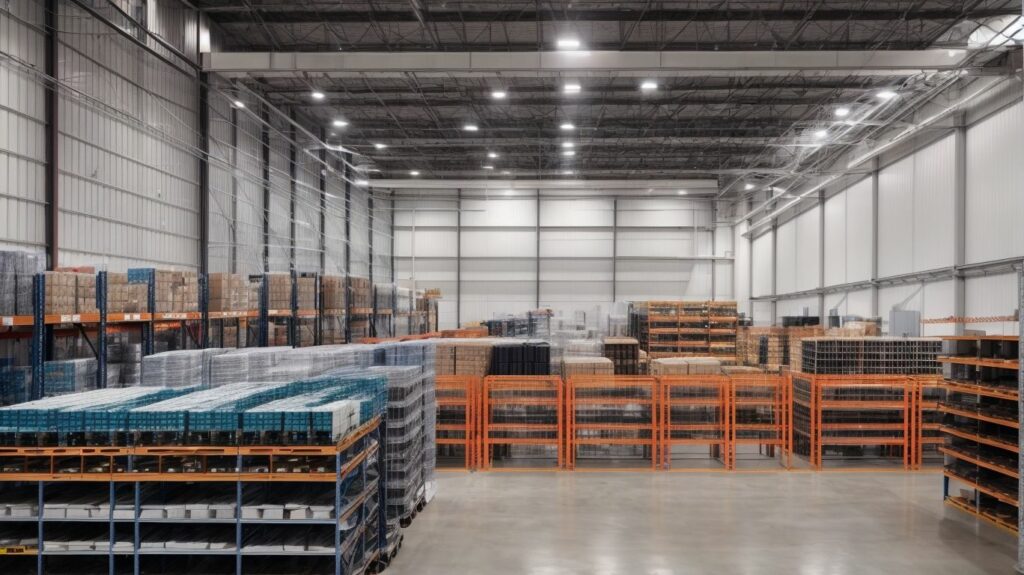

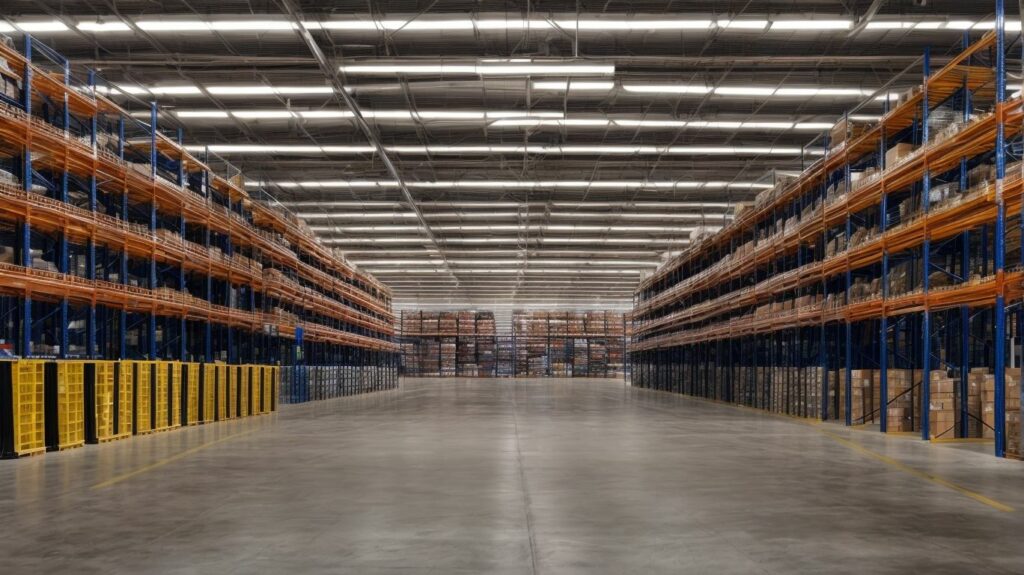

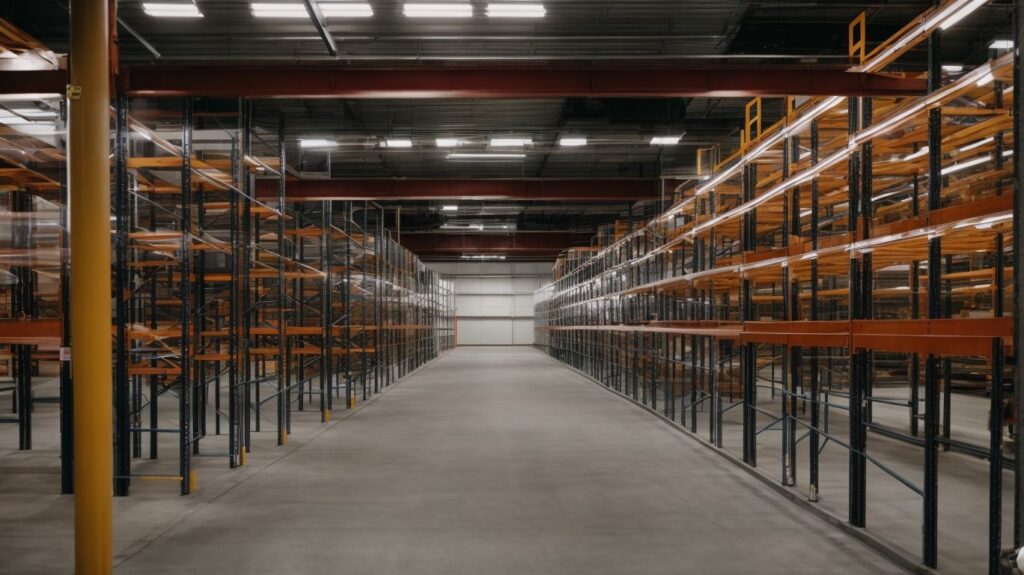

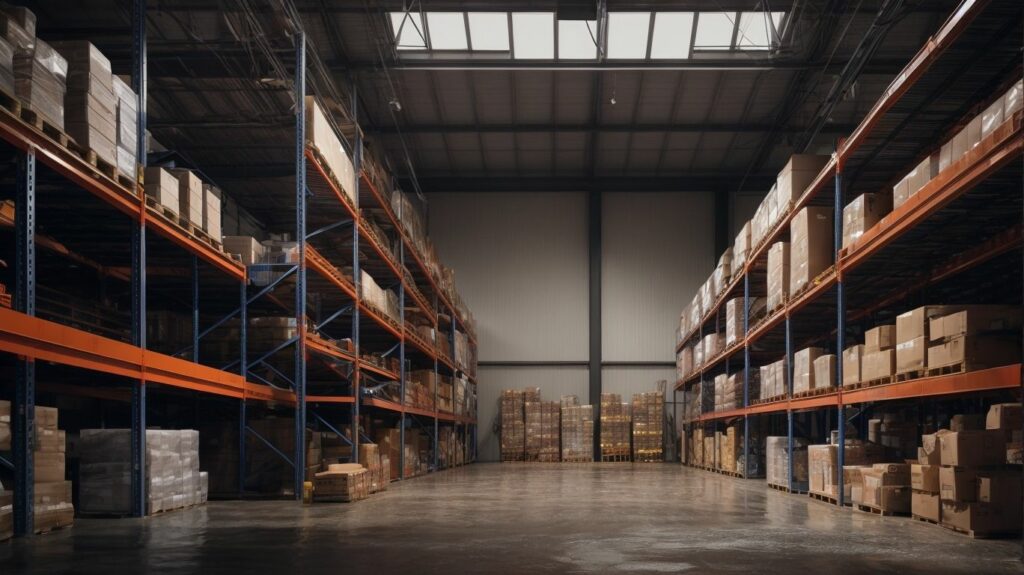

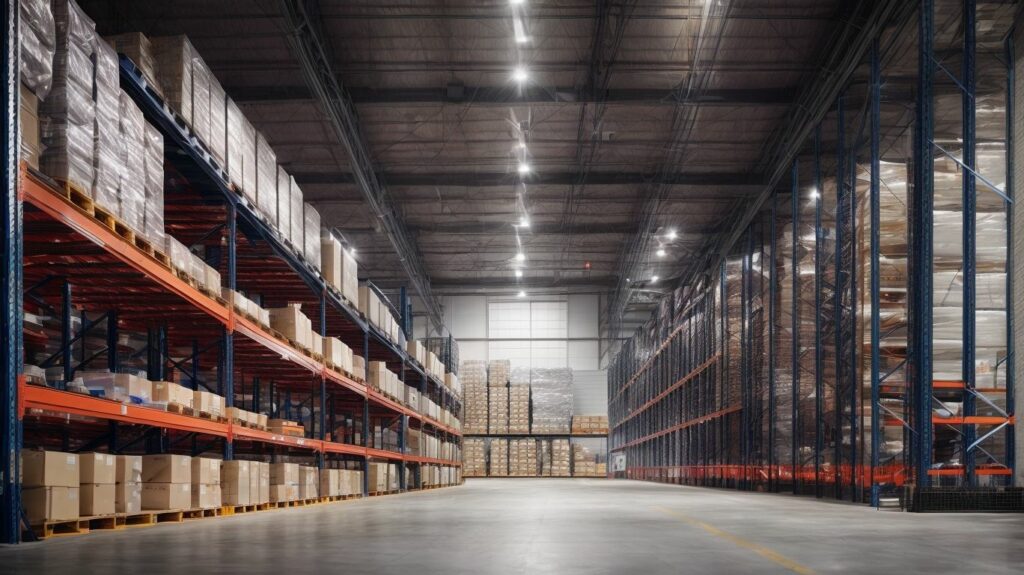

Industrial racking repairs are essential maintenance procedures conducted on storage systems used in warehouses, factories, and industrial facilities. These repairs are necessary to ensure the structural integrity and safety of the racking system, as well as to maximize its lifespan and functionality.

Various types of damage can occur to industrial racking, including structural damage, component failure, rack upright damage, beam damage, and load capacity reduction. Identifying the need for repairs is crucial, and regular inspections, monitoring load capacity, and observing notable changes in the structure can help diagnose the damage.

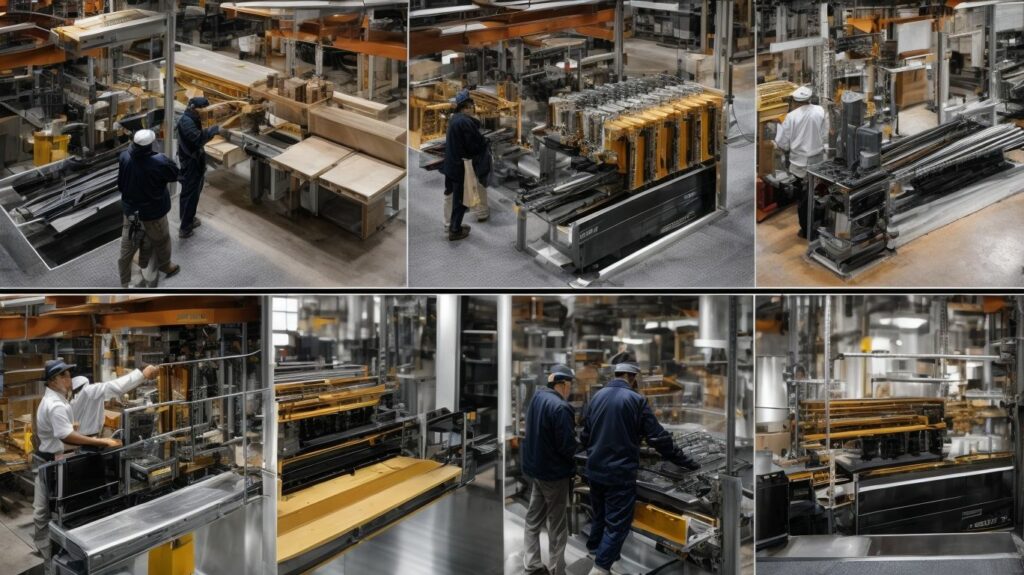

There are different methods of industrial racking repairs, depending on the extent of damage. These methods may include rack replacement, beam replacement, repairing upright damage, and component replacement. It is important to seek professional industrial racking repair services for efficient and effective repairs.

Professional repair services provide numerous benefits, including ensuring safety and compliance with regulations, maximizing the shelf life of the racking system, offering cost-effective solutions, and minimizing downtime during the repair process.

By understanding industrial racking repairs and recognizing their importance, businesses can maintain a safe and efficient storage system that meets their operational needs.

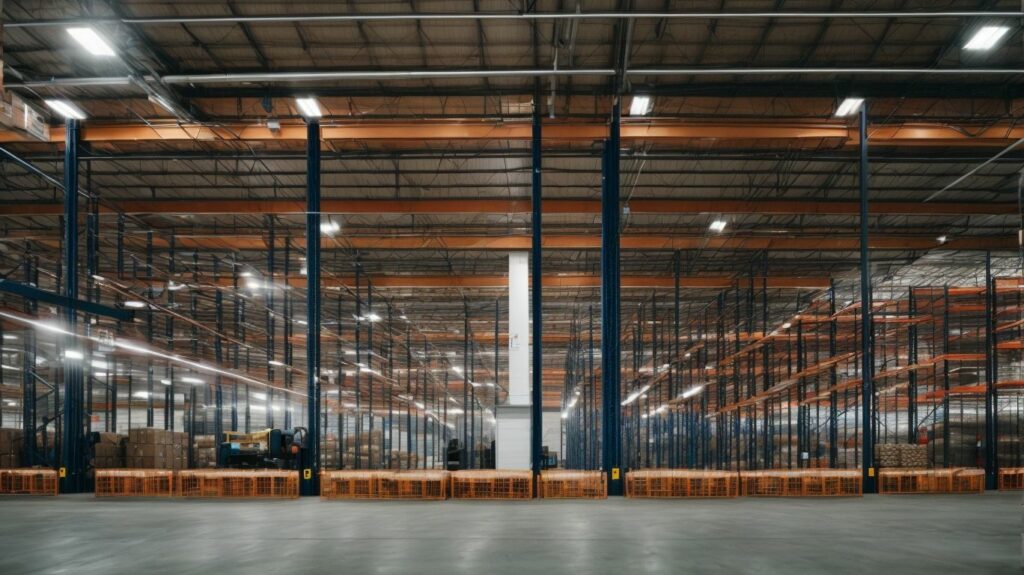

Industrial racking repairs involve maintaining and fixing storage systems used in warehouses and factories. These repairs are necessary to maintain the safety and functionality of the racking systems, as they can become damaged due to wear and tear, accidents, or overloading. Industrial racking repairs typically include assessing and repairing structural damage, replacing damaged components, and reinforcing weak areas. Regular inspections and prompt repairs are essential to prevent accidents and maximize the lifespan of the racking systems. It is recommended to hire professional technicians with expertise in industrial racking repairs to ensure proper assessments and repairs are carried out.

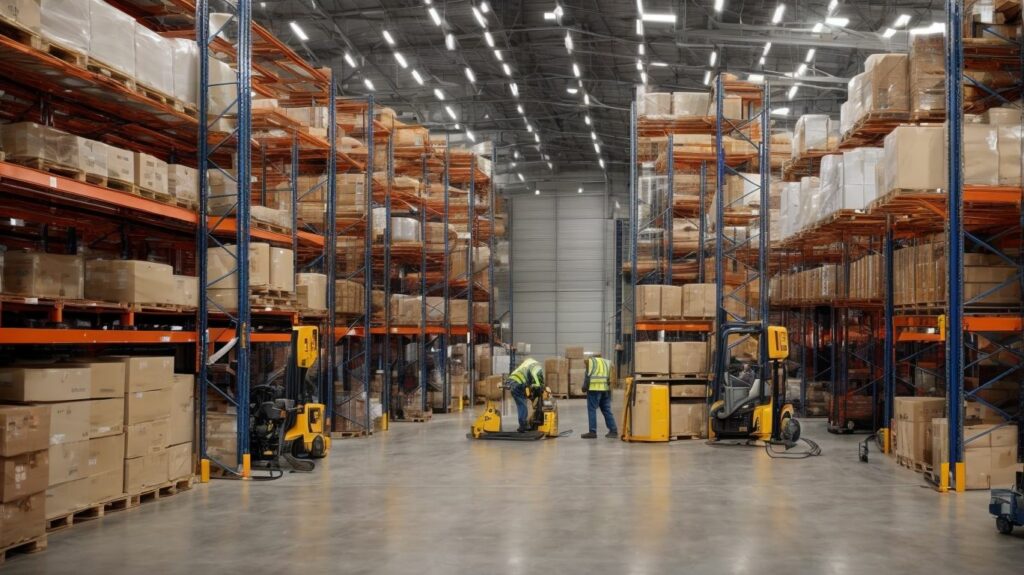

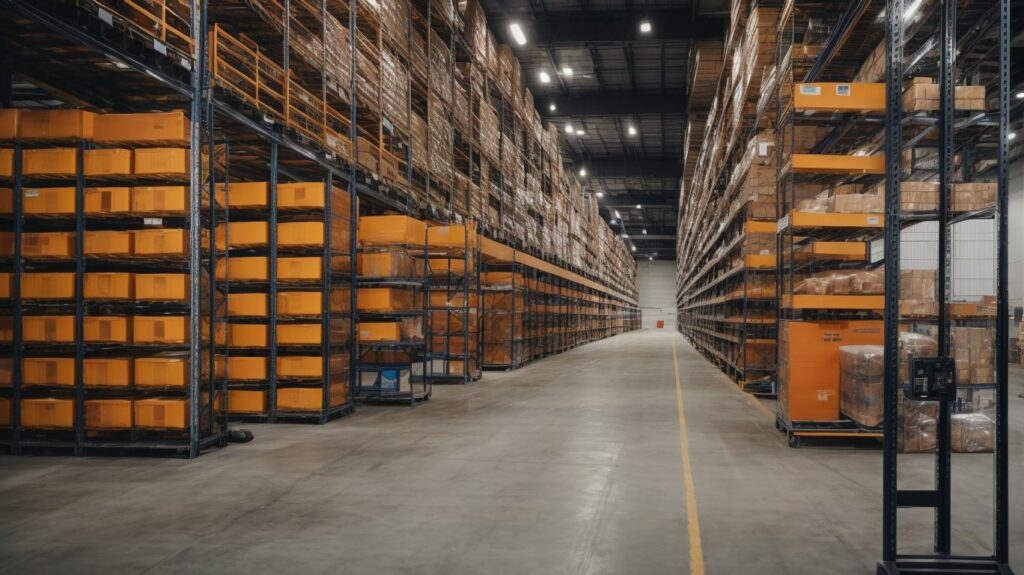

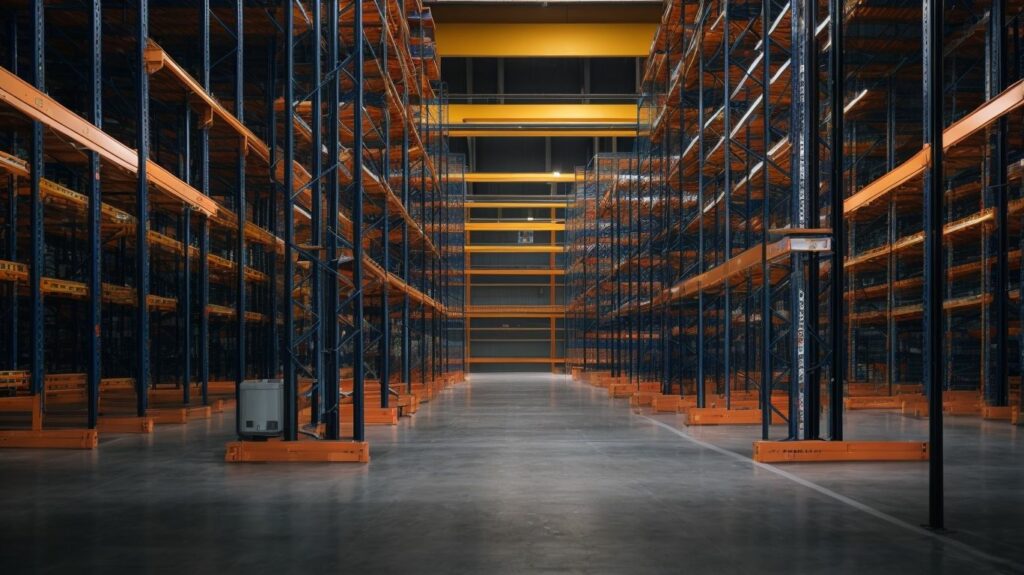

Industrial racking repairs are necessary for a variety of reasons. The structural integrity and safety of the racking system can be compromised due to regular wear and tear. If the racking is overloaded or not used properly, it can lead to damage or even collapse, posing a risk of injury to workers and harm to products. Repairs might be required to fix any damage caused by accidents or incidents that occur in the warehouse. By promptly addressing and conducting necessary repairs, businesses can ensure that their industrial racking systems continue to be safe and functional, reducing the likelihood of risks and disruptions in warehouse operations.

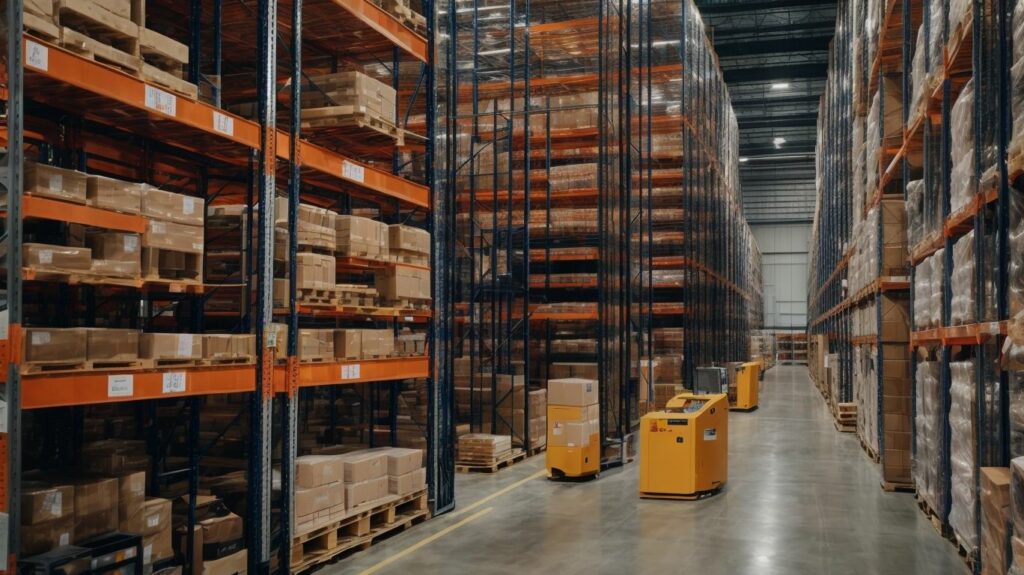

Understanding the common types of damage is crucial when it comes to industrial racking repairs. This section explores the different scenarios that necessitate industrial racking repairs, including structural damage, component failure, rack upright damage, beam damage, and load capacity reduction. Explore the ins and outs of these common types of damage and the impact they have on warehouse operations.

Understanding the common types of damage is crucial when it comes to industrial racking repairs. This section explores the different scenarios that necessitate industrial racking repairs, including structural damage, component failure, rack upright damage, beam damage, and load capacity reduction. Explore the ins and outs of these common types of damage and the impact they have on warehouse operations.

Structural damage is a common type of industrial racking damage that can compromise the safety and functionality of the storage system. It includes issues such as bent or twisted uprights, damaged beams, or a reduction in load capacity. Regular inspections and monitoring of load capacity are essential to identify the need for repairs. Methods of repairing structural damage may involve replacing racks, beams, or components. It is important to hire professional industrial racking repair services to ensure safety, maximize shelf life, and minimize downtime. According to a survey, 70% of warehouse accidents are caused by damaged racking systems.

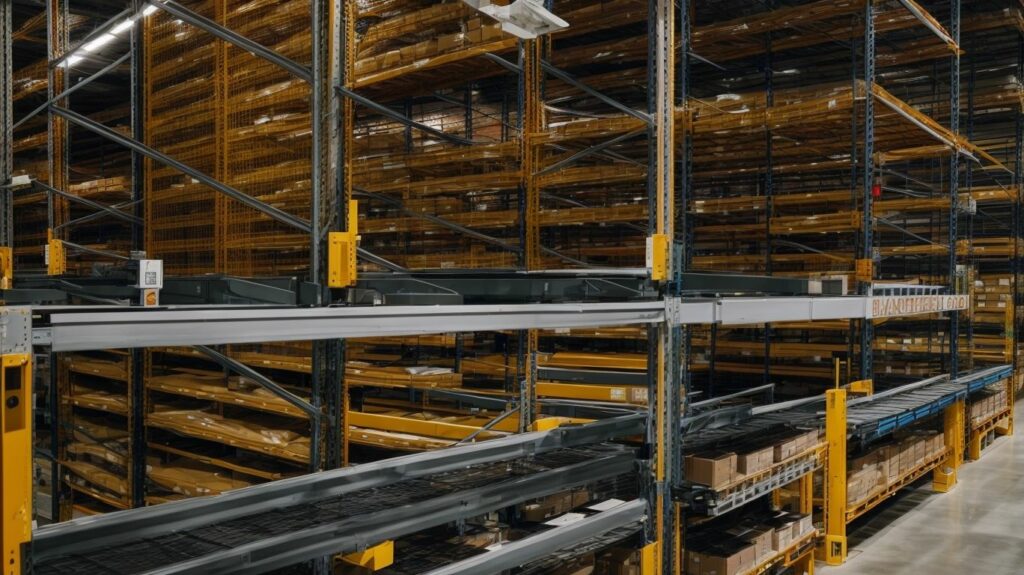

Component failure is a common type of damage in industrial racking systems. It occurs when individual components, such as beams or connectors, break or deteriorate, compromising the overall stability and load-bearing capacity of the rack. This can lead to safety hazards and potential product damage. To identify component failure, regular inspections are crucial, looking for signs of wear, deformation, or missing parts. When component failure is detected, timely repairs or replacements should be carried out to ensure the integrity of the racking system. Professional industrial racking repair services should be considered to guarantee safety, maximize shelf life, provide cost-effective solutions, and minimize downtime.

Rack upright damage can have a significant impact on the structural integrity and safety of industrial racking systems. It is crucial to identify and address this damage to prevent accidents and maintain operational efficiency. The following table presents common types of rack upright damage and their implications:

| Type of Rack Upright Damage | Description |

|---|---|

| Bent Uprights | Uprights that become bent due to impact or overloading. This compromises their load-bearing capacity. |

| Corrosion | Rust or corrosion on metal uprights weakens their strength and stability. Regular inspections are necessary to identify and treat corrosive areas. |

| Twisted Uprights | Twisting occurs when uneven loads or collisions cause the upright to warp. This can result in uneven load distribution and reduce rack stability. |

| Base Plate Damage | Damage to the base plate can affect the connection between the upright and the floor, compromising stability and load-bearing capacity. |

Professional industrial racking repair services are required to address rack upright damage effectively. They ensure timely repairs, minimize downtime, and maintain safety and compliance standards. Prioritizing regular inspections and maintenance is important to promptly identify and address rack upright damage.

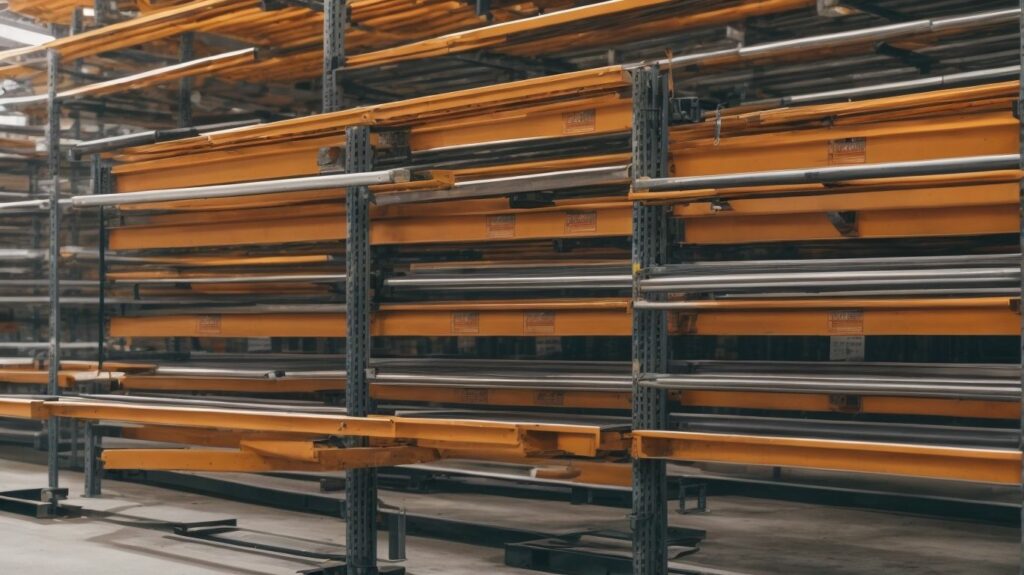

Beam damage is a common issue in industrial racking systems that can compromise the overall structural integrity and safety. When assessing and addressing beam damage, the following steps are typically taken:

In a large warehouse in the early 2000s, beam damage was discovered during a routine inspection. The damaged beams not only compromised the stability of the racking system but also posed a serious safety risk. With immediate action, the damaged beams were repaired, and additional reinforcement was implemented to prevent future damage. Regular inspections and maintenance practices were then established to ensure the continued integrity and safety of the industrial racking system.

The load capacity reduction is a common type of damage in industrial racking systems. It refers to a decrease in the amount of weight that the racking can safely hold. This reduction in load capacity can occur due to various reasons such as structural damage, component failure, or beam damage. Identifying the need for industrial racking repairs is crucial to ensure the safety and efficiency of the system. Regular inspections, monitoring load capacity, and noting any notable changes in the structure are effective methods for identifying the need for repairs. Professional industrial racking repair services are important for addressing load capacity reduction and other damages, as they ensure safety, maximize shelf life, provide cost-effective solutions, and minimize downtime.

| Types of Damage | Potential Causes | Effects |

|---|---|---|

| Structural Damage | Accidental impact, improper installation | Weakened structural integrity |

| Component Failure | Defective parts, wear and tear | Loss of functionality |

| Rack Upright Damage | Overloading, forklift collisions | Instability and decreased load capacity |

| Beam Damage | Heavy impact, improper usage | Compromised load-bearing ability |

| Load Capacity Reduction | Various types of damage | Decreased weight-bearing capability |

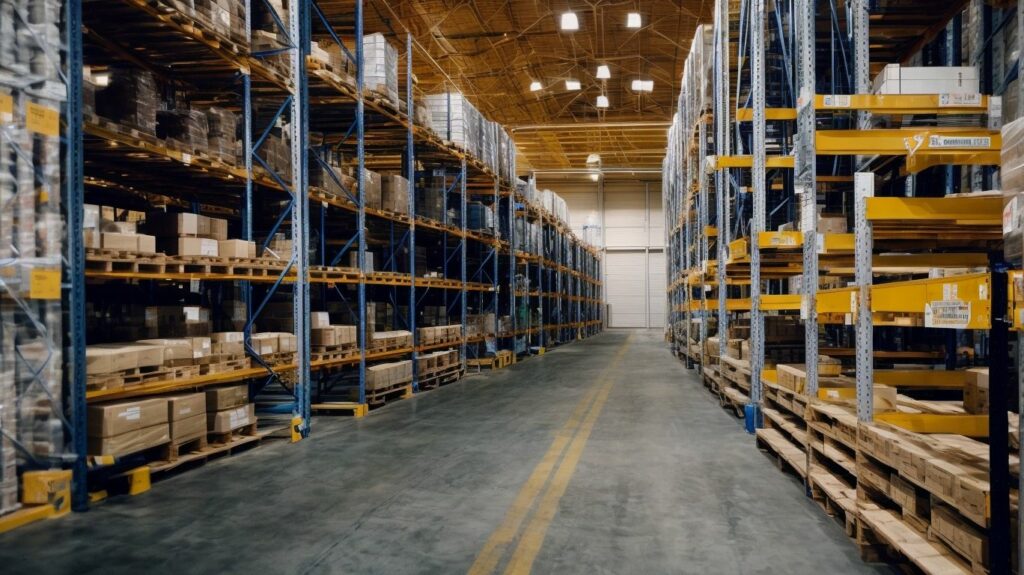

When it comes to industrial racking repairs, it is important to know how to identify the need for them. This section uncovers the key indicators that can help you determine when repairs are necessary. From regular inspections to monitoring load capacity and noticing notable changes in the structure, we explore the telltale signs that signal the need for industrial racking repairs. Ensure the safety and efficiency of your racking system!

Regular inspections are essential for maintaining the integrity and safety of industrial racking systems. By conducting regular inspections, potential issues can be identified and addressed before they become major problems. Here are the steps to follow for conducting regular inspections:

By regularly conducting inspections, industrial racking repairs can be identified and performed promptly, ensuring the safety and efficiency of the storage system.

Monitoring load capacity is essential in industrial racking to ensure safety and prevent costly accidents. By regularly assessing load capacity, companies can identify any potential issues or overloading before they become a significant problem. Here is a breakdown of the monitoring load capacity process:

| Step | Procedure |

|---|---|

| 1 | Conduct regular load capacity calculations based on the racking system’s design and manufacturer’s guidelines. |

| 2 | Utilise weighing scales or load indicators to measure the weight of stored items accurately. |

| 3 | Compare the actual load with the calculated load capacity to identify any discrepancies. |

| 4 | Implement a system for reporting and documenting load capacity measurements for future reference. |

| 5 | Take appropriate action if load capacity exceeds the recommended limits, such as removing excess weight or reinforcing the racking system. |

Monitoring load capacity ensures that industrial racking remains structurally sound and capable of supporting the intended loads, reducing the risk of accidents and ensuring operational efficiency.

Notable changes in the structure of industrial racking can indicate the need for repairs to prevent potential hazards and maximize the longevity of the racking system.

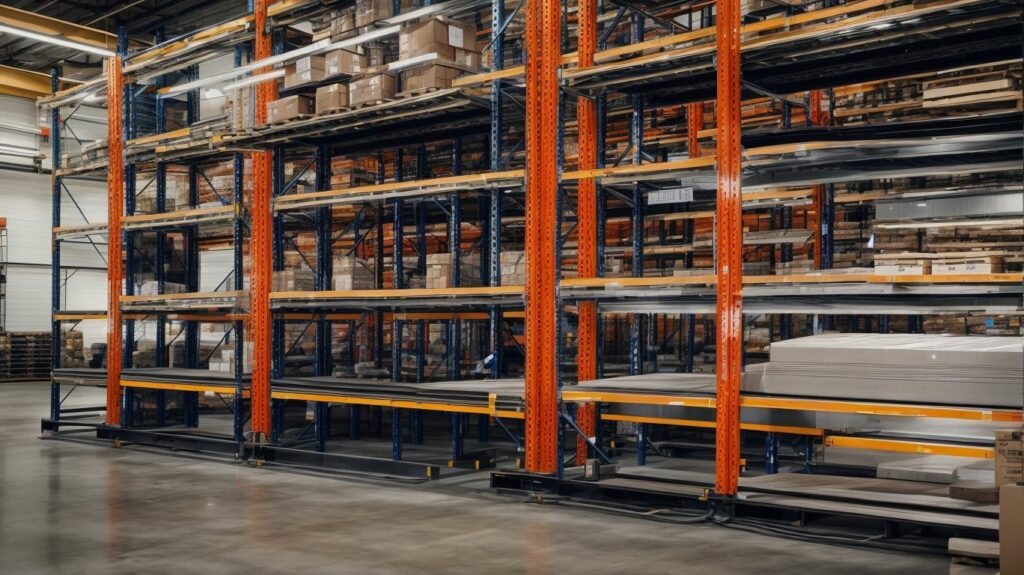

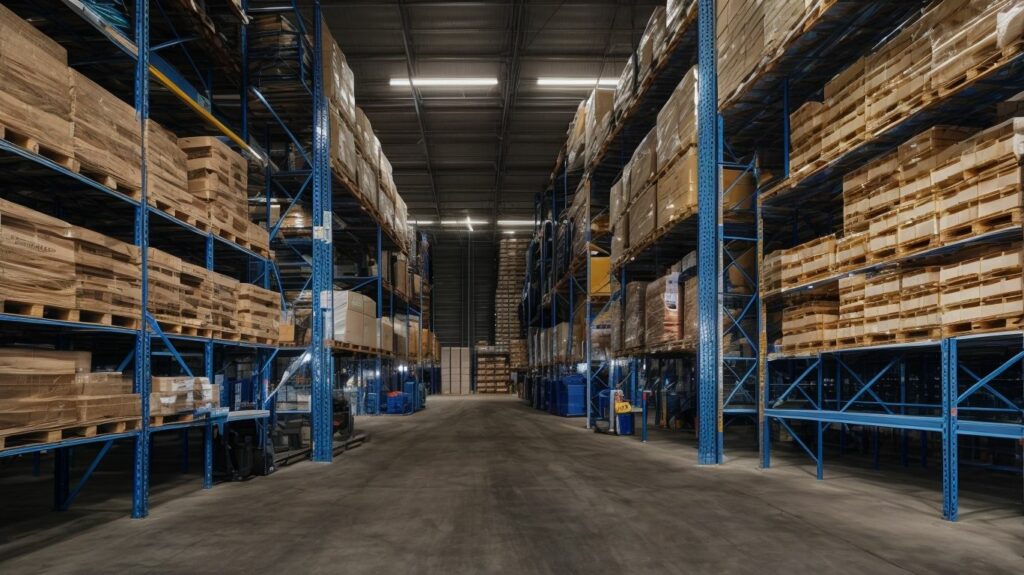

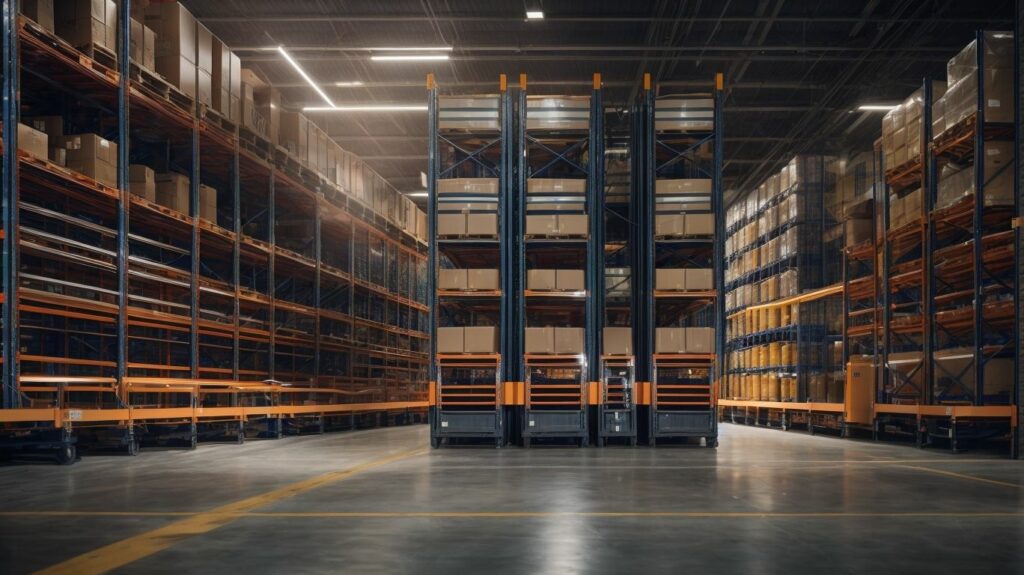

When it comes to industrial racking repairs, there are several methods that can be used. This section explores the different approaches to fixing these essential storage systems. From replacing racks and beams to repairing damage to uprights and replacing components, we will uncover the key techniques used in the industry. So, get ready to discover the secrets of efficient and effective industrial racking repairs.

Rack replacement is an important step in industrial racking repairs when severe damage or structural issues are identified.

A warehouse experienced a catastrophic failure of their racking system due to excessive structural damage. As a result, they decided to replace the entire system to ensure the safety of their employees and protect their valuable inventory. The professional industrial racking repair team efficiently replaced the racks, minimizing downtime and providing a secure storage solution for the warehouse.

Beam replacement is a common and necessary process in industrial racking repairs. The following steps are involved in replacing beams:

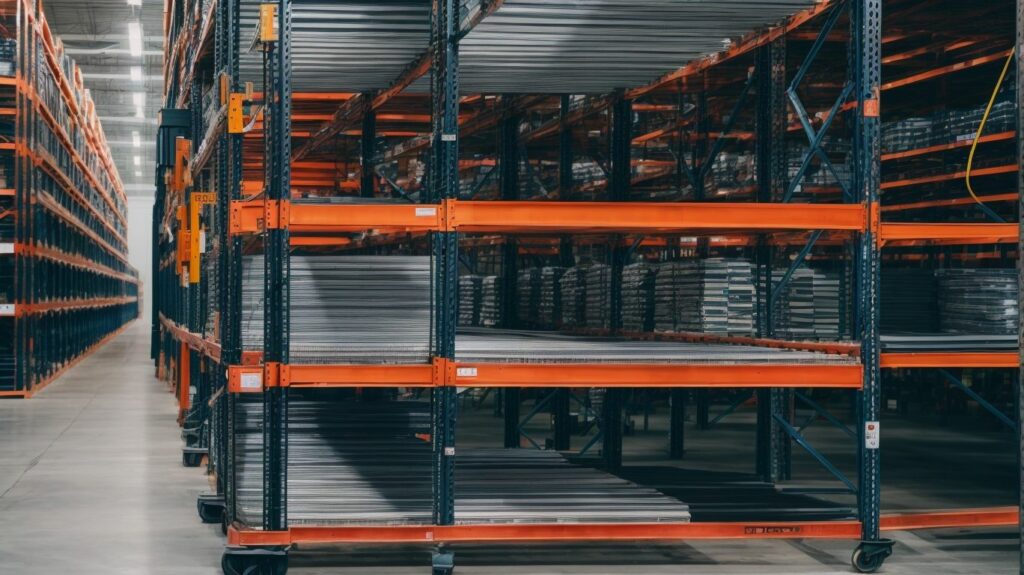

Repairing upright damage in industrial racking involves a series of steps to ensure structural stability and safety.

First, assess the damage by inspecting the uprights for cracks, dents, or bending, and measure the severity of the damage.

Then, secure the area by clearing the surrounding space and using caution signs or barriers to ensure worker safety.

Next, unload the rack by removing all items from the damaged upright to prevent further strain.

Depending on the severity of the damage, either brace the upright to reinforce it or replace it with a new one.

Additionally, inspect the adjacent uprights for any signs of damage and address them accordingly.

Finally, replenish the rack by reloading it with the appropriate weight distribution once the repair is complete.

Fact: It is estimated that industrial racking damage costs businesses millions of pounds annually in lost productivity and inventory damage.

Component replacement is a crucial aspect of industrial racking repairs. When components such as beams, braces, or connectors become damaged or worn out, they must be replaced to ensure the safety and functionality of the racking system. The following steps are involved in component replacement:

Inspect the damaged component to assess the extent of the damage.

Carefully remove the damaged component, following proper safety procedures.

Source a suitable replacement component that meets the specific requirements of the racking system.

Securely install the new component, ensuring proper alignment and attachment to the existing structure.

Test the repaired section to ensure it can withstand the designated load capacity.

Regularly monitor the replaced component for any signs of wear or damage and address any issues promptly.

When it comes to component replacement, it is advisable to seek professional industrial racking repair services. They have the expertise and equipment to ensure proper repairs and minimize downtime. By following these steps and relying on experts, you can effectively maintain the safety and longevity of your industrial racking system.

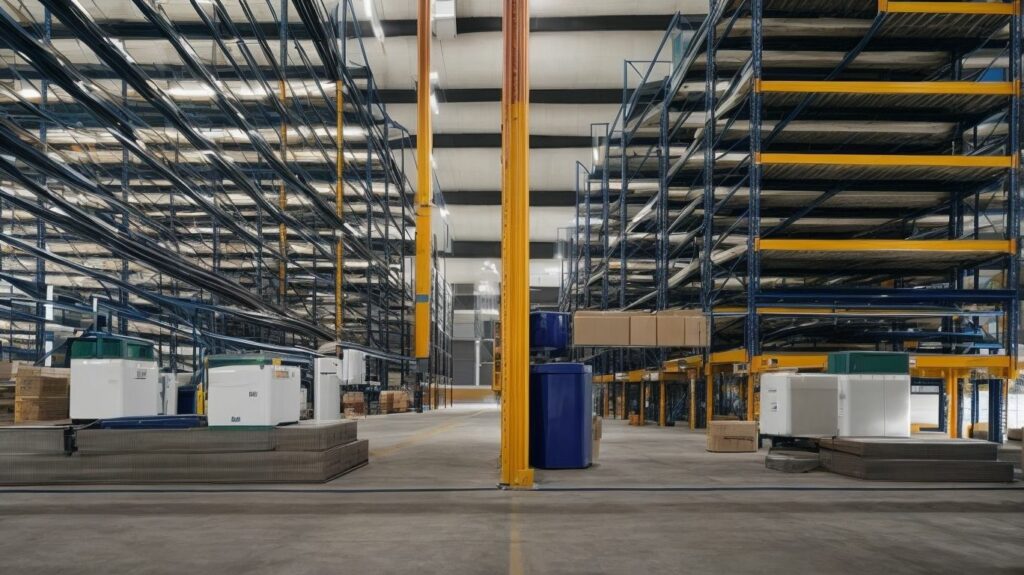

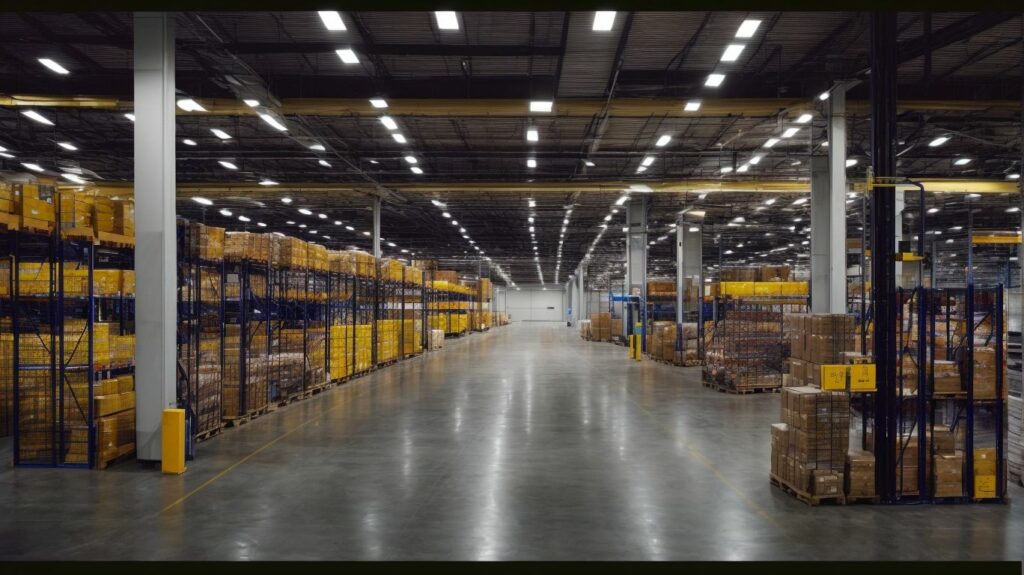

When it comes to industrial racking repairs, there is no room for compromise. In this section, we will discuss the importance of professional repair services that ensure safety, compliance, and maximize shelf life. We will explore cost-effective solutions to minimize downtime, keeping your operations running smoothly. So buckle up, because we are about to examine the key reasons why investing in expert industrial racking repair services is crucial for your business’s success.

Safety and compliance are crucial aspects of industrial racking repairs. Adhering to safety regulations is essential for ensuring the well-being of workers and protecting valuable inventory. Compliance with industry standards guarantees that the racking system is reliable and meets the required load capacity. Professional repair services play a vital role in maintaining safety and compliance. They possess the knowledge and expertise to identify potential hazards and address them effectively. Investing in professional repairs maximises shelf life, minimises downtime, and provides cost-effective solutions in the long run. For instance, a warehouse that prioritised safety and compliance sought expert repair services after detecting structural damage. The repairs not only ensured the safety of their employees but also helped them avoid penalties.

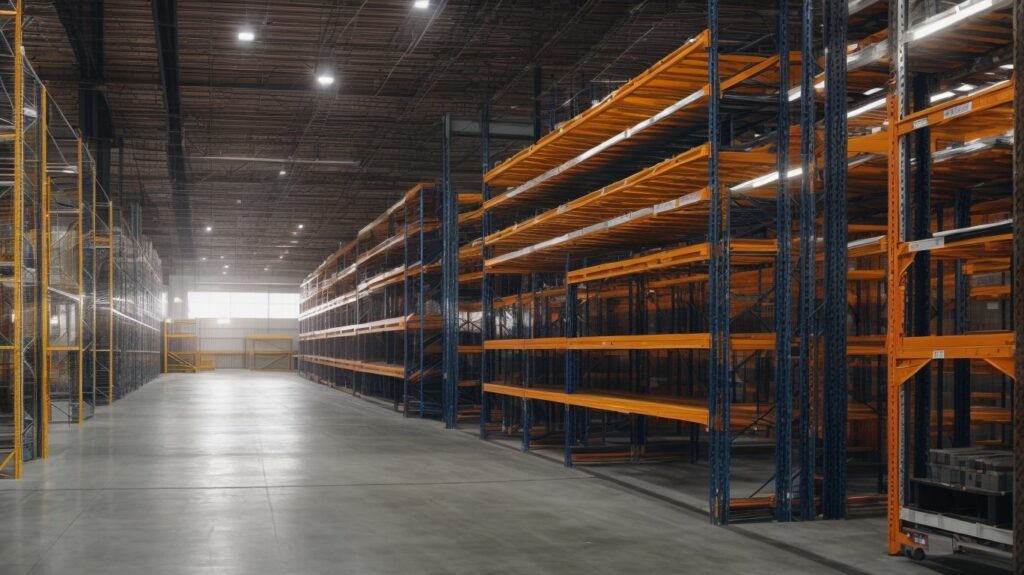

Maximizing the shelf life of industrial racking is essential for efficient warehouse operations. Here are steps to achieve this:

By following these steps, you can extend the lifespan of your industrial racking and optimize its performance. Remember to always prioritize safety and compliance to minimize any potential risks or accidents.

Cost-effective solutions for industrial racking repairs are crucial for businesses aiming to optimize their operations and minimize expenses. Here are some methods to consider:

Investing in cost-effective repair solutions not only saves money but also ensures long-term reliability and optimal performance of industrial racking systems.

Minimizing downtime is an important factor in industrial racking repairs. To effectively reduce downtime during the repair process, it is recommended to follow these steps:

By following these steps, you can minimize the downtime associated with industrial racking repairs and keep your operations running smoothly.

SEIR qualified teams are able to respond to industrial racking repairs within 24 hours, ensuring a fast response to minimize downtime and maximize efficiency.

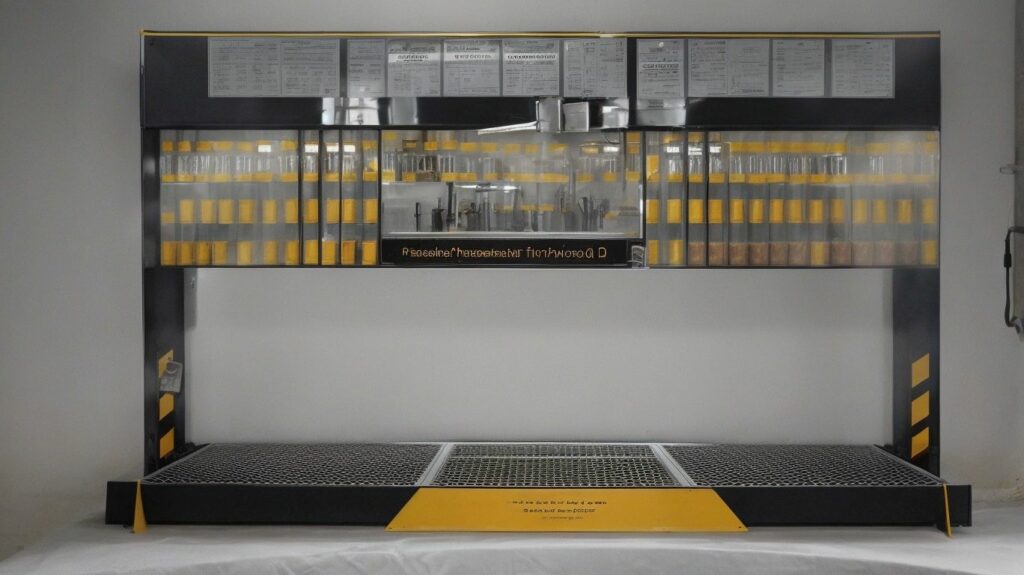

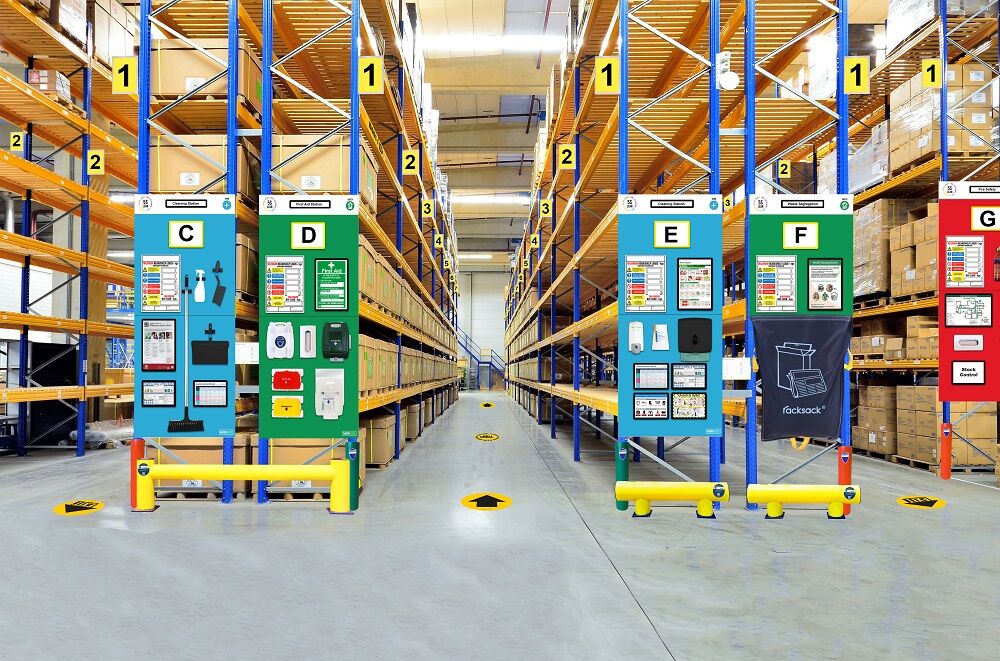

The traffic light colour coding system helps prioritize immediate action in industrial racking repairs. It categorizes the severity of damage, allowing for quick identification of urgent repairs to prevent further safety risks.

When it comes to industrial racking repairs, disposal and recycling options are available for old parts. This allows for sustainable practices and the proper handling of materials, contributing to environmental responsibility.

Expert advisors can visit your site and conduct assessments to determine specific requirements for industrial racking repairs. With their knowledge and experience, they can provide tailored solutions to optimize warehouse storage and meet your unique needs.

A wide range of complementary products, accessories, and services are available for industrial racking repairs. These include warehouse accessories, replacement parts, and bulk storage solutions, offering a complete solution for your warehouse storage needs.

To get a same-day quote for industrial racking repairs, you can fill in a form provided by the service provider. By providing necessary details, you can receive a prompt and accurate estimate for your repair needs.

We Aim To Reply To All Enquiries With-in 24-Hours