20+ Years Experience

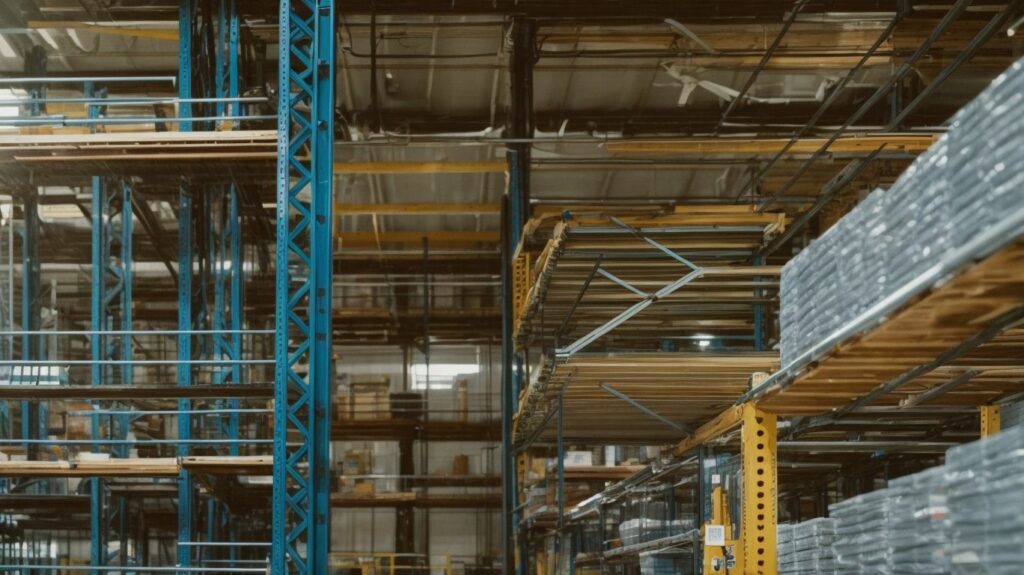

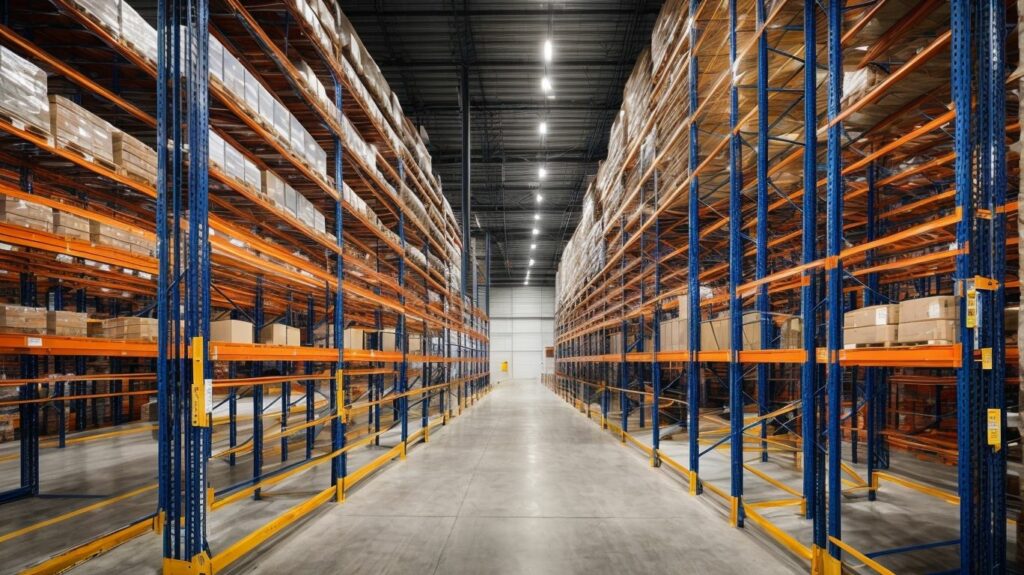

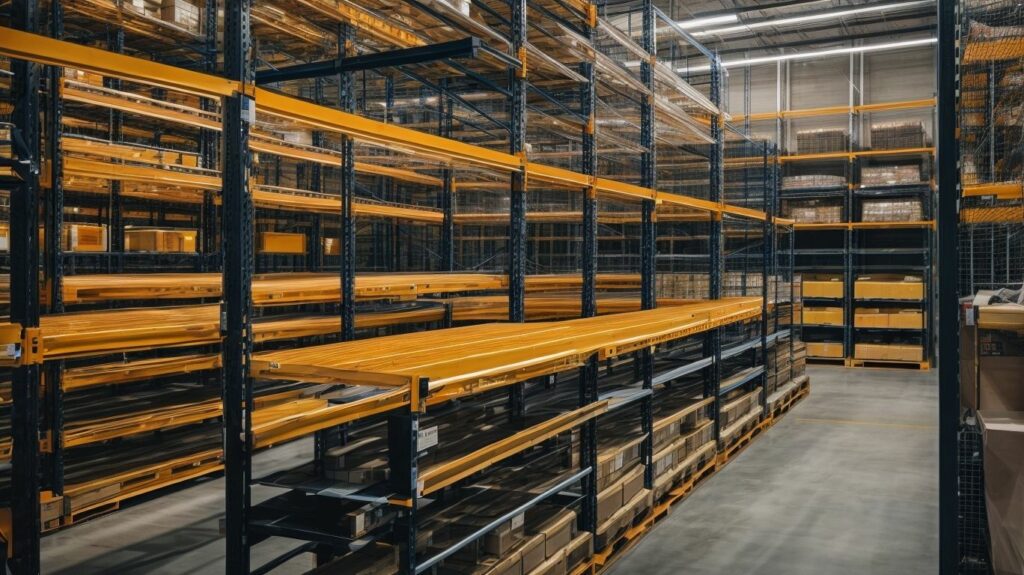

Specialist Pallet Racking

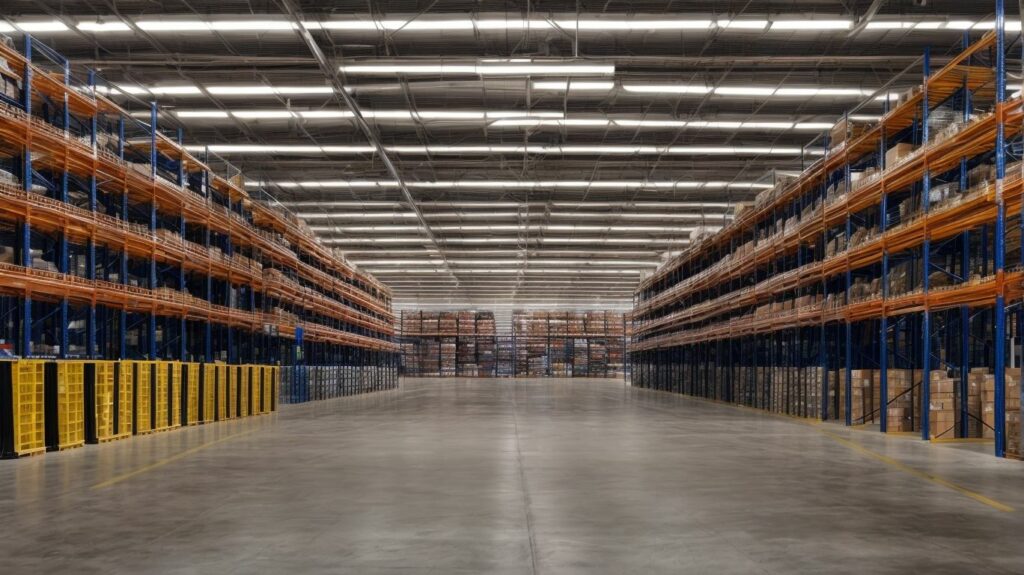

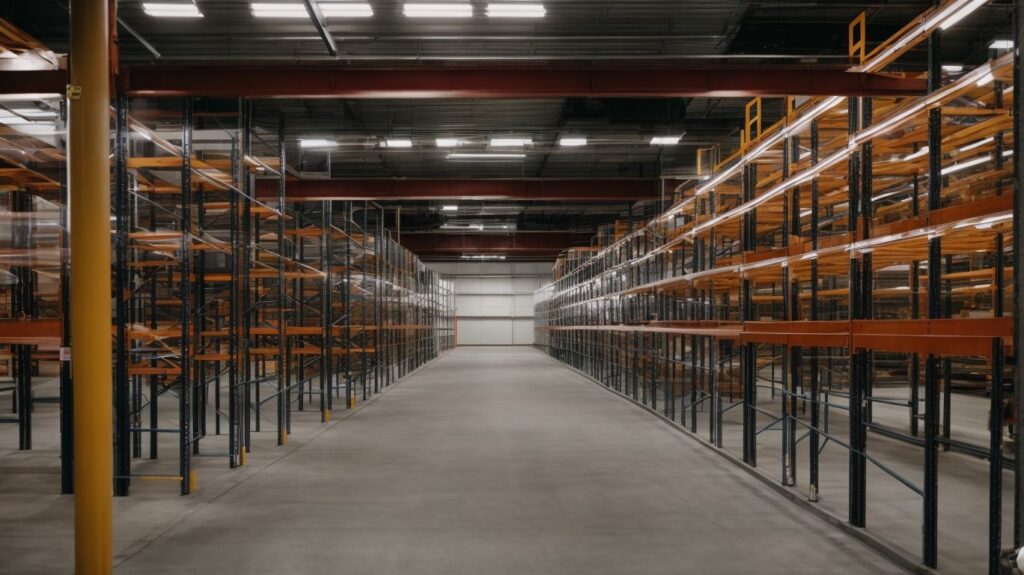

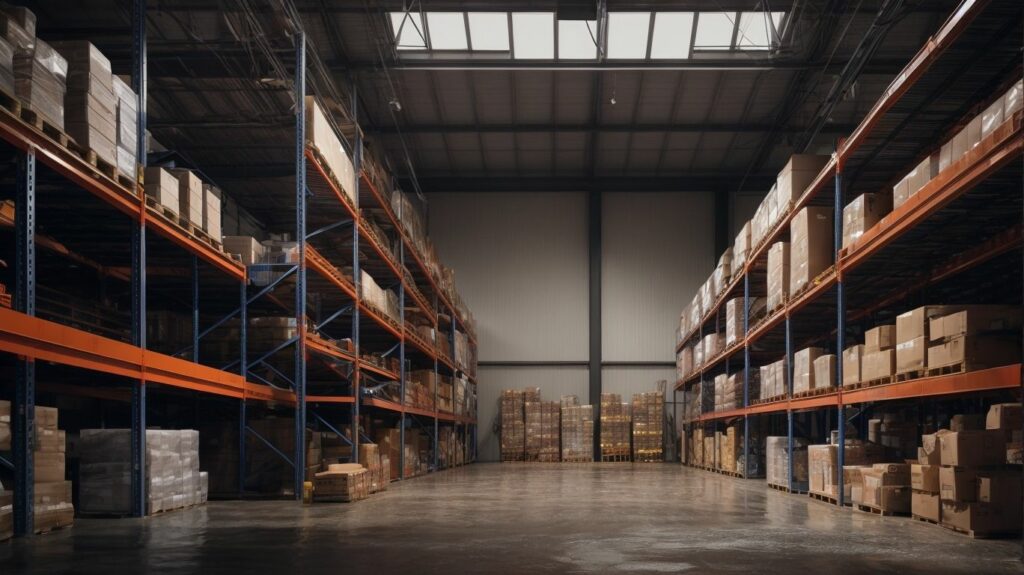

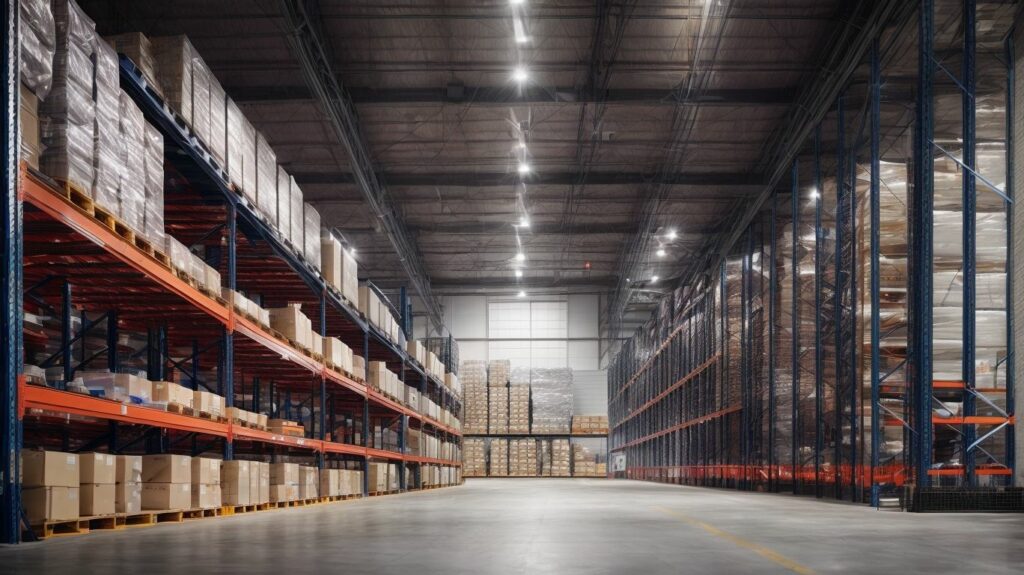

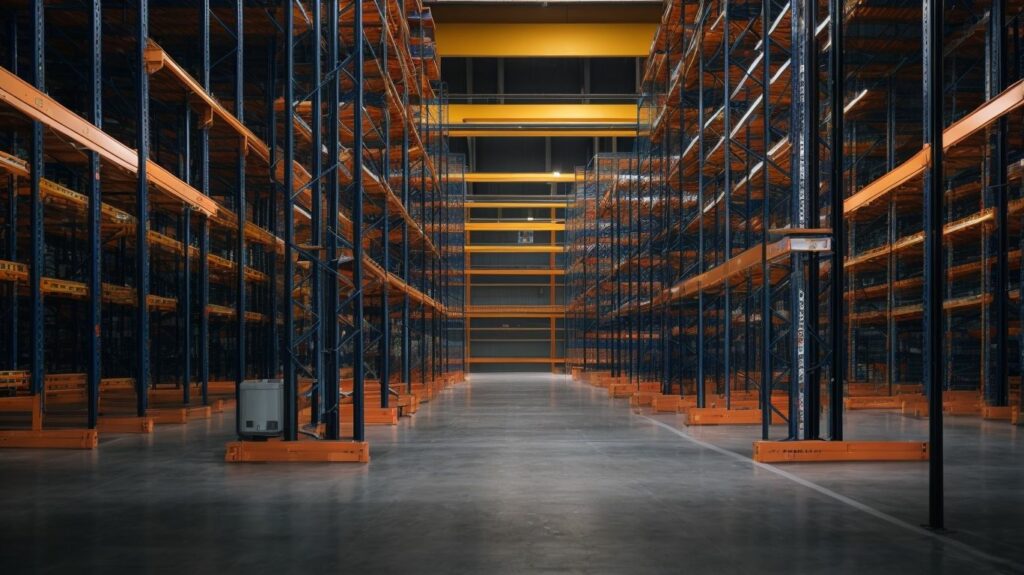

SEMA racking, also known as Storage Equipment Manufacturers Association racking, is a type of industrial racking system commonly used in warehouses and storage facilities to organize and store products efficiently. It is designed to withstand heavy loads and maximize storage space.

The importance of SEMA racking repairs cannot be overstated. Regular maintenance and repairs are essential to ensure the safety and integrity of the racking system. SEMA racking repairs are crucial for several reasons.

Firstly, maintaining SEMA racking is important to prevent accidents and injuries. Damaged racking can collapse under the weight of the stored items, posing a significant risk to employees and damaging valuable inventory.

Secondly, timely repairs help prolong the lifespan of the racking system. By addressing any damage promptly, you can prevent it from worsening and avoid costly replacements in the long run.

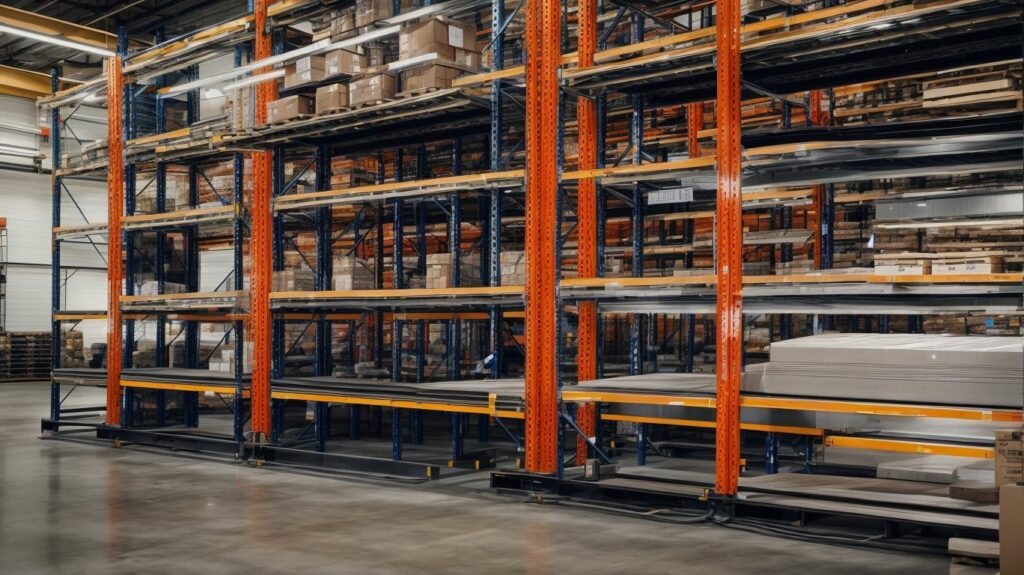

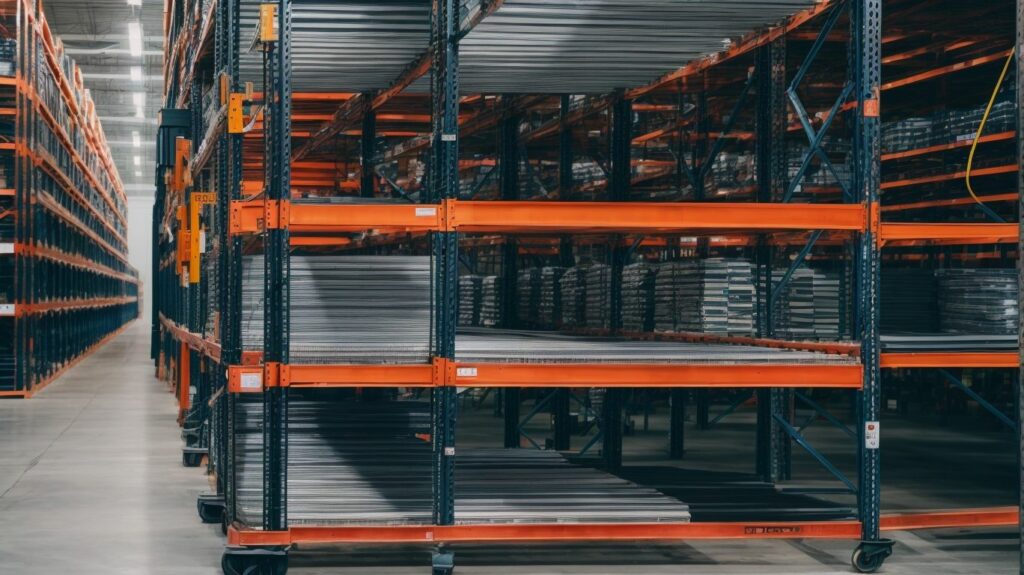

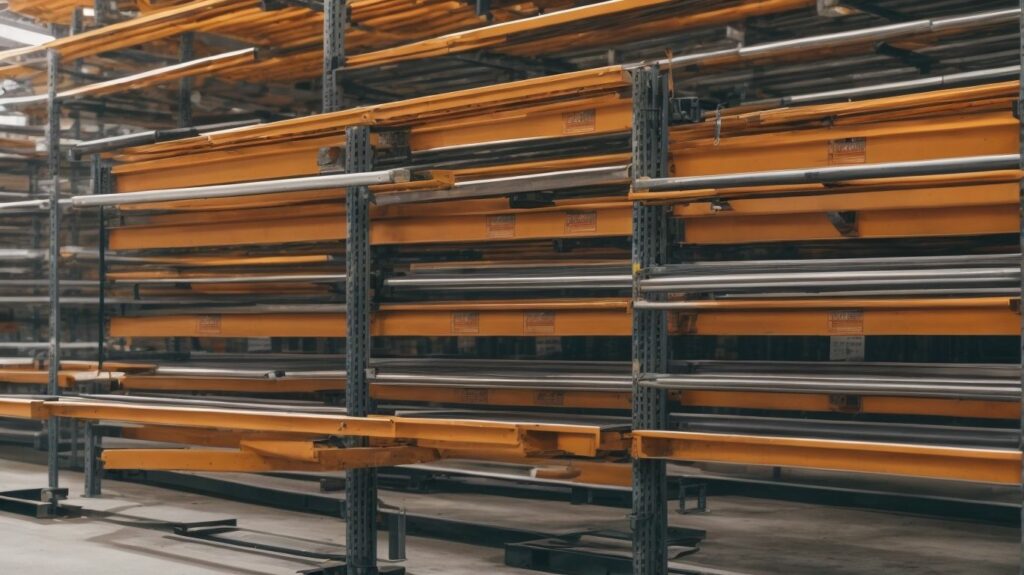

Common types of SEMA racking damage include bent beams, twisted frames, corroded components, and damaged uprights. These issues can occur due to improper use, accidental impacts, or general wear and tear over time.

To determine if SEMA racking repairs are needed, there are several signs to look out for. Visible damage, such as bent or misaligned beams, is an obvious indication that repairs are necessary. Unusual noises, such as creaking or rattling, can also suggest underlying damage. If the racking appears to be shifting or misaligned, immediate attention is required.

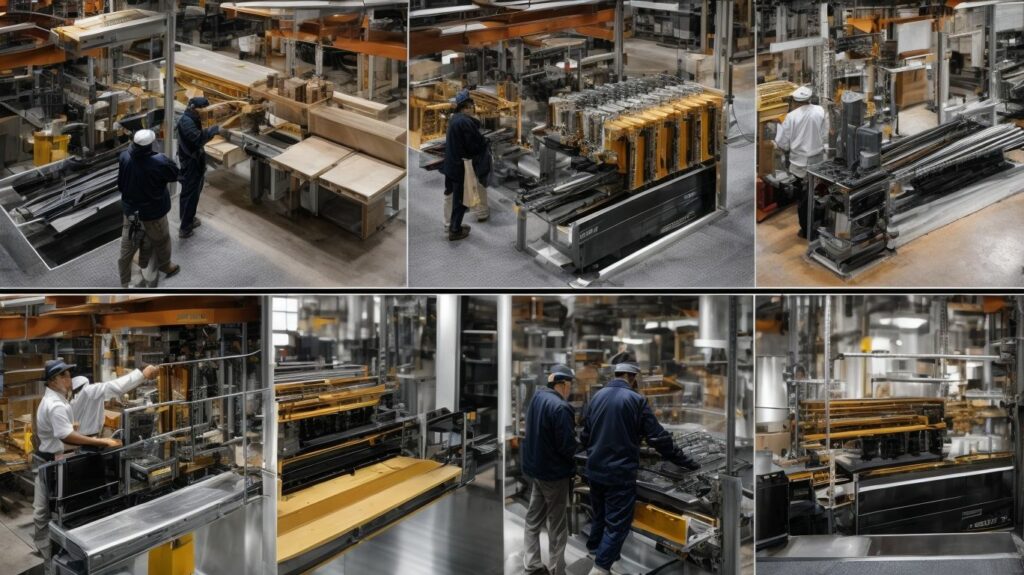

When performing SEMA racking repairs, a thorough inspection and assessment should be conducted to identify all damaged components. These components should then be replaced with new ones to ensure the stability and strength of the racking system. Reinforcement and strengthening measures may also be undertaken to further enhance the integrity of the racks.

It is important to note that SEMA racking repairs should be carried out by professionals experienced in working with industrial racking systems. Their expertise and knowledge ensure that the repairs are done correctly, following industry best practices and safety guidelines.

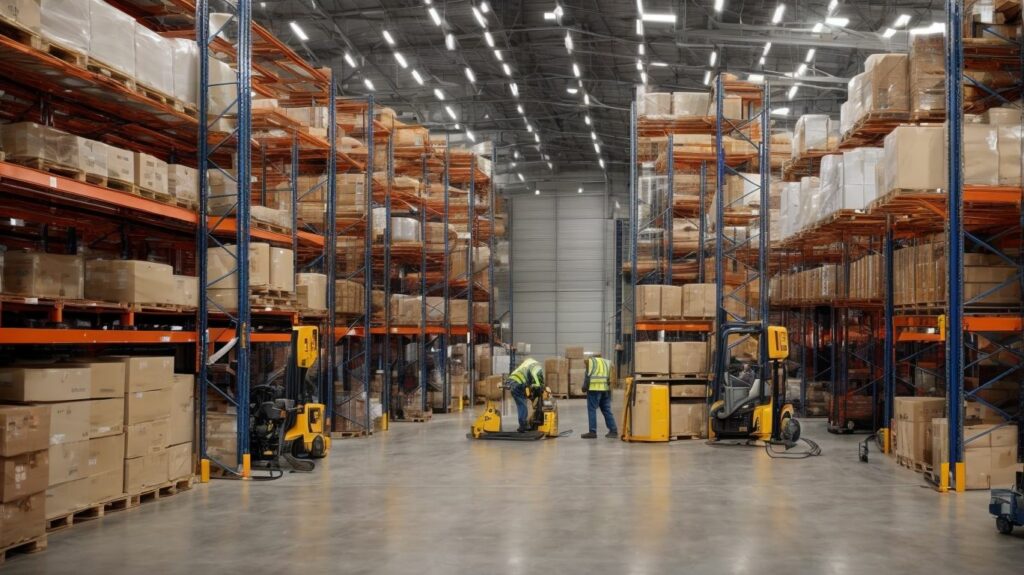

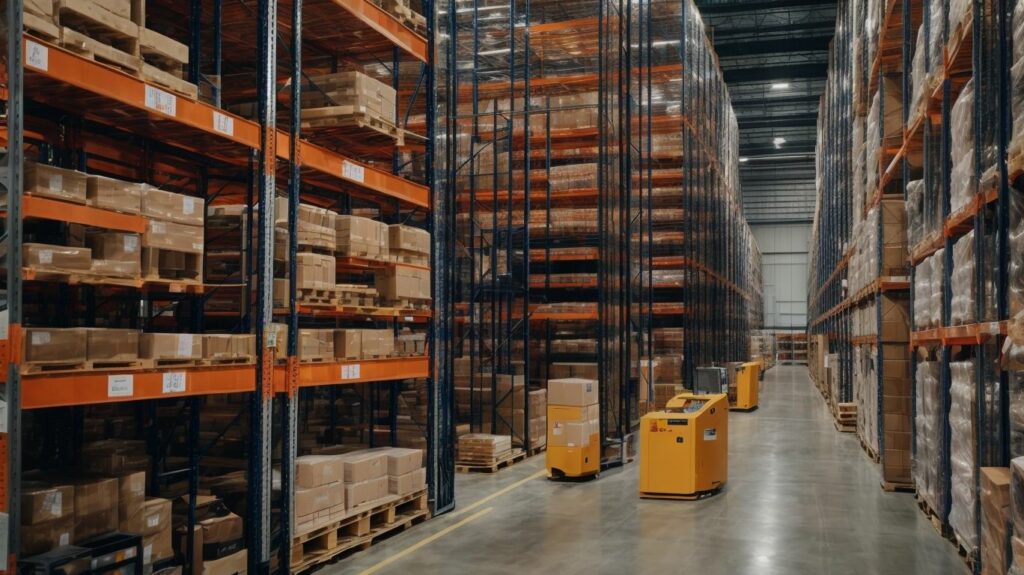

To prevent future SEMA racking damage, proper loading and weight distribution should be maintained. The correct handling and use of equipment, such as forklifts, is crucial to avoid accidental impacts. Regular inspections and maintenance should be scheduled to detect any signs of damage early on and address them promptly.

By prioritizing SEMA racking repairs and implementing preventive measures, you can ensure the safety, longevity, and optimal functionality of your industrial storage system.

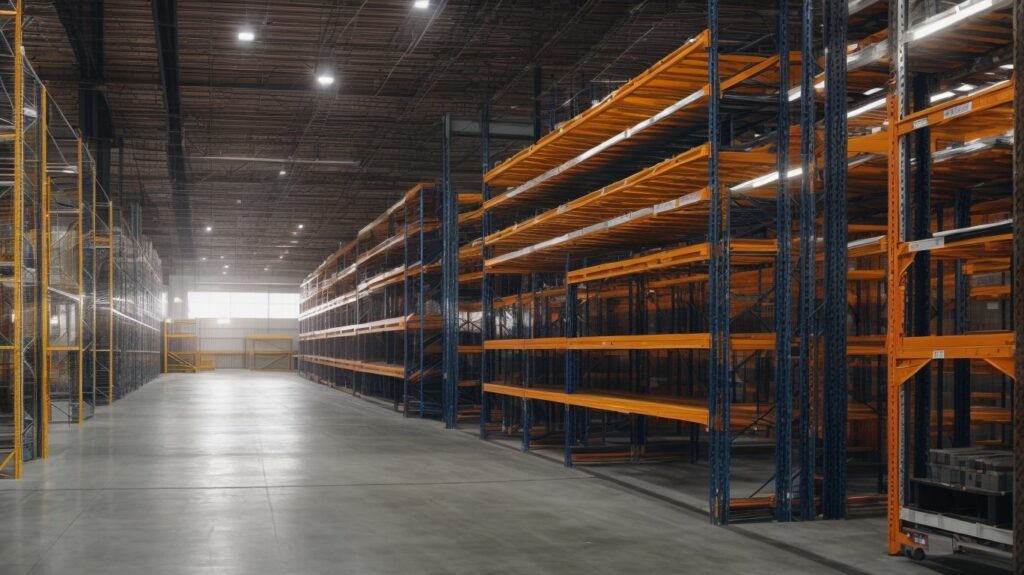

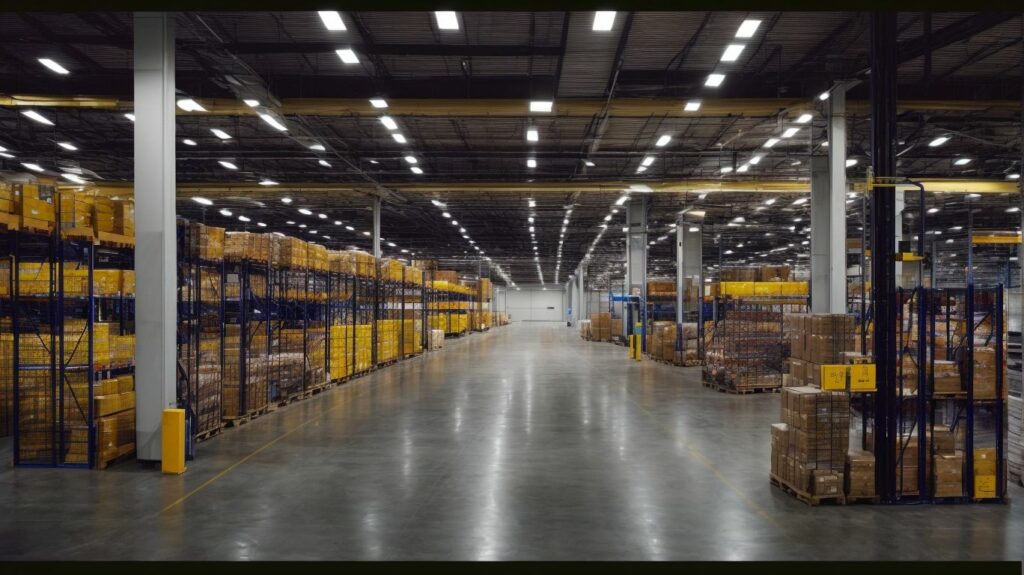

SEMA Racking, which stands for Storage Equipment Manufacturers Association Racking, is a commonly used industrial storage system in warehouses and distribution centres. It is designed to maximise vertical storage space and provide efficient access to stored goods. SEMA Racking consists of vertical frames, horizontal beams, and shelves or pallets for supporting and organising items. This versatile system can be easily adjusted or expanded to accommodate changing storage needs. Proper installation and maintenance of SEMA Racking are crucial for ensuring safety and optimising storage capacity.

The importance of SEMA racking repairs cannot be overstated. Regular maintenance and repairs ensure the safety and functionality of the racking system. Damaged or faulty racks can pose serious risks to employees and result in costly accidents or damage to stored goods. Proper repairs help prevent collapses, optimize storage capacity, and extend the lifespan of the racking system. Ignoring repairs can lead to legal liabilities and interruptions in business operations. Prioritize the safety and efficiency of your warehouse by not overlooking the significance of SEMA racking repairs.

True History Example:

In 2014, a warehouse in the UK experienced a catastrophic racking collapse due to neglecting SEMA racking repairs. The incident resulted in severe injuries to several workers and extensive damage to stored inventory. This unfortunate event highlighted the critical importance of regular inspections and repairs to ensure the safety and well-being of employees, as well as the smooth functioning of warehouse operations. It served as a wake-up call for businesses to prioritize and invest in SEMA racking repairs to avoid such devastating accidents.

Maintaining SEMA racking is essential for several reasons. It ensures the structural integrity of the racking system, preventing accidents and injuries. Regular maintenance helps identify any damage or issues early on, allowing for timely repairs and avoiding costly replacements. Proper maintenance also extends the lifespan of the racking, maximizing its efficiency and value. By maintaining SEMA racking, you demonstrate a commitment to safety and professionalism in the workplace. To ensure the longevity of SEMA racking, it is advisable to schedule regular inspections, perform repairs promptly, and train employees on proper loading and handling techniques. Implementing a preventive maintenance program can help stay on top of potential issues and minimise downtime.

When it comes to SEMA racking, it is important to be aware of the common types of damage that can occur. From bent beams to twisted frames, corroded components to damaged uprights, this section discusses the various issues that can compromise the integrity of your racking system. Let’s delve into the facts and figures, supported by reliable sources, and examine the challenges associated with each type of damage. Prepare to discover the key insights into SEMA racking repairs.

Bent beams are a common type of damage found in SEMA racking systems. They occur when there is a significant impact or pressure applied to the beams, causing them to bend. This can compromise the overall structural integrity of the racking and pose a safety risk. To highlight the importance of addressing this issue promptly, here’s a true story: In a warehouse, a bent beam went unnoticed, leading to a collapse that caused significant damage to the stored inventory and posed a threat to workers’ safety. Regular inspections and prompt repairs are crucial to prevent such incidents and ensure the proper functioning of SEMA racking systems.

| Bent Beam | Caused by impact or excessive pressure on the beams | Compromises structural integrity | Potential safety risk |

By following these steps and seeking professional SEMA racking repair services when necessary, you can ensure the safety and longevity of your SEMA racking system.

Corroded components in SEMA racking can compromise the structural integrity and safety of the storage system. It is important to promptly identify and address this issue. Below is a table outlining the signs and effects of corroded components:

| Signs | Effects |

| Discolouration | Reduced load-bearing capacity |

| Rust formation | Increased risk of component failure |

| Pitting or flaking | Compromised structural stability |

To prevent corroded components, regular inspections and maintenance are essential. Implementing corrosion-resistant coatings and addressing any signs of rust early can help extend the lifespan of SEMA racking systems.

Fun Fact: According to SEMA (Storage Equipment Manufacturers Association), properly maintained racking systems can have a service life of up to 20 years or more!

When it comes to SEMA racking, damaged uprights can pose a serious risk to the safety and stability of the entire rack system. Here are some common types of damage to uprights:

If you notice any of these signs of damaged uprights, it is crucial to address the issue promptly to prevent further damage or collapse of the racking system. Repairs may involve the replacement of the damaged uprights and reinforcing the rack system to ensure its stability and safety.

If your SEMA racking is displaying visible damage, producing unusual noises, or shifting/misaligning, it is crucial to take notice. These indications signify that SEMA racking repairs are required. Do not underestimate the significance of maintaining the integrity of your racking system. This section will delve into these signs in greater detail, equipping you with the knowledge to identify potential problems and take the appropriate measures to guarantee a secure and effective warehouse environment. Prioritize safety above productivity!

Visible damage on SEMA racking is a clear indication that repairs are needed. Regular inspection of the racking is important to identify any signs of visible damage, such as bent beams, twisted frames, corroded components, or damaged uprights. These issues can compromise the integrity and safety of the racking system. Once damage is identified, repairs should be promptly carried out. This typically involves inspecting and assessing the extent of the damage, replacing damaged components, reinforcing and strengthening the structure, and conducting regular maintenance and inspections to prevent future damage. It is crucial to utilize professional SEMA racking repair services to ensure proper and effective repairs.

Unusual noises in SEMA racking can be an indication of potential problems that require immediate attention. These noises can range from creaking and squeaking to loud bangs or rattling sounds. Some possible causes for these noises include damaged beams, loose connections, or misaligned components. It is crucial to address the issue promptly to prevent further damage or potential accidents. Regular inspections and maintenance can help identify and resolve issues before they escalate. If you hear unusual noises coming from your SEMA racking, it is recommended to contact a professional repair service to assess and resolve the issue promptly.

Shifting or misaligned racking is a common issue in SEMA racking systems that can compromise safety and efficiency. Here are steps to address this problem:

By following these steps, you can effectively address shifting or misaligned racking in your SEMA racking system and maintain a safe and efficient storage solution.

Looking to carry out SEMA racking repairs? This section will cover the process. We will delve into each step, including inspection, assessment, replacement of damaged components, reinforcement and strengthening, and regular maintenance and inspections. You will learn how to ensure the safety and reliability of your SEMA racking system. No more guesswork – we’ve got you covered!

When it comes to SEMA racking repairs, it is important to start with a thorough inspection and assessment of the damage. This will help in identifying the necessary repairs and carrying them out effectively.

By following these steps, you can ensure that the damaged components in your SEMA racking system are replaced effectively, maintaining the integrity and safety of the storage system.

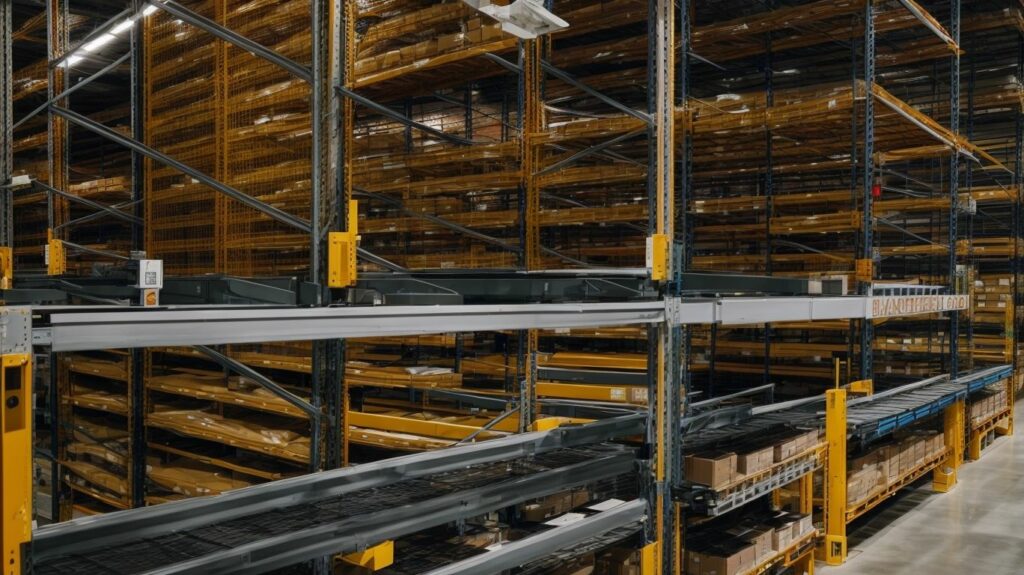

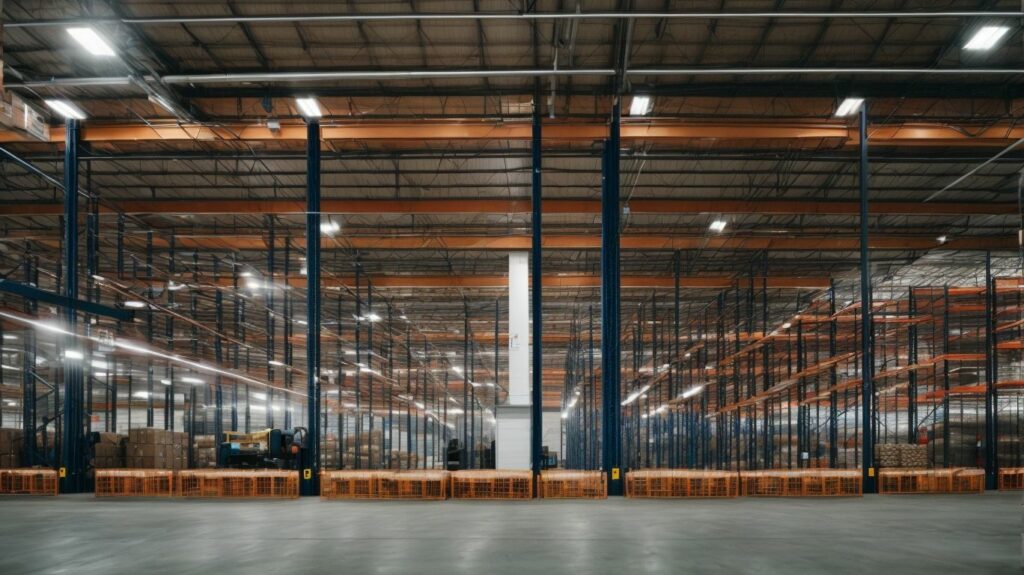

Reinforcement and strengthening of SEMA racking is essential to ensure its structural integrity and prevent further damage or accidents. The following steps should be followed to perform reinforcement and strengthening:

Thoroughly inspect the racking system to identify any weak or damaged areas.

Replace any damaged or weakened components, such as bent beams or corroded parts.

Add additional supports, such as cross bracing or column protectors, to enhance the stability of the racking.

Consider reinforcing critical areas with reinforcement plates or angle brackets.

Pro-tip: Regularly monitor and maintain the SEMA racking system to promptly address any potential issues and prevent the need for extensive repairs in the future.

Regular maintenance and inspections are crucial for maintaining the safety and efficiency of SEMA racking. Follow these steps to ensure proper maintenance:

It’s important to remember that regular maintenance and inspections not only prolong the lifespan of SEMA racking but also contribute to a safer and more efficient working environment.

In 2019, a warehouse experienced a major racking collapse due to inadequate maintenance and inspections. It resulted in significant damage to stored goods and posed serious safety risks to employees. Since then, the company implemented a strict regimen of regular maintenance and inspections, ensuring the safety and functioning of their SEMA racking system. No further incidents have occurred, and the company continues to prioritize regular maintenance as an essential part of their operations.

The Importance of Professional SEMA Racking Repair Services

Professional SEMA racking repair services are essential for maintaining warehouse safety and efficiency. Promptly repairing damaged racking is vital to prevent accidents and protect valuable inventory. Attempting DIY repairs or relying on inexperienced technicians can result in further damage and pose a safety risk. Professional repair services ensure that industry standards and regulations are followed, guaranteeing a high level of quality and compliance. For instance, a real-life incident highlights the significance of professional SEMA racking repair services: A company failed to address a damaged rack, which eventually led to a collapse and substantial inventory loss. Investing in professional repairs could have prevented this costly incident.

To ensure the longevity of SEMA racking systems, it is important to focus on preventing future damage. This section will discuss essential measures that can be taken to prevent such damage. We will look at proper loading techniques, weight distribution, and the correct handling of equipment, exploring how these practices are crucial for maintaining the integrity of SEMA racking. Regular inspections and maintenance will also be emphasised, highlighting their contribution to a safe and well-functioning racking system. Let’s now delve into these practices and safeguard the future of your SEMA racking.

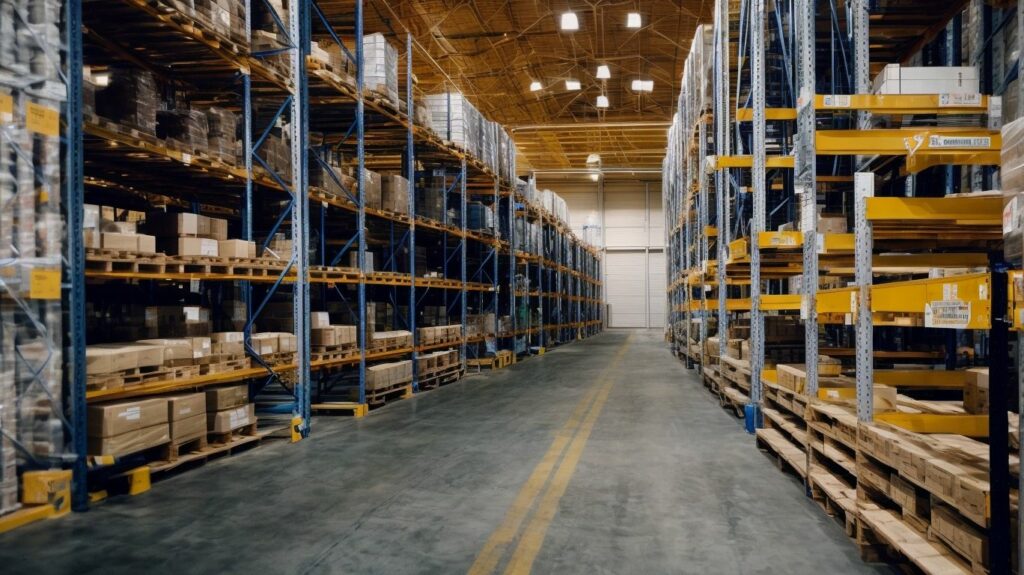

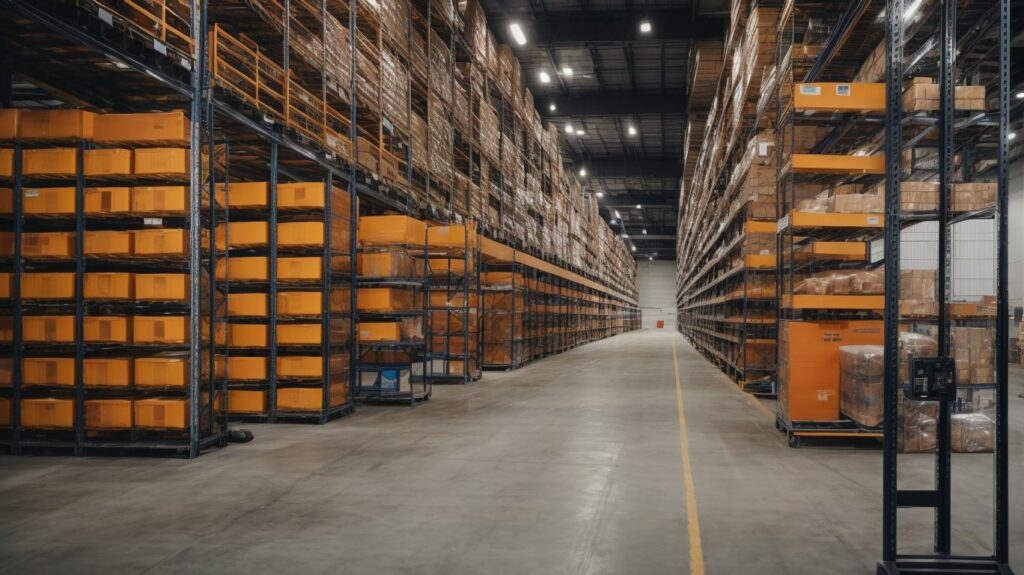

Proper loading and weight distribution are essential for ensuring the safety and stability of SEMA racking systems. To achieve this, follow these steps:

Proper handling and use of equipment are crucial for maintaining and prolonging the lifespan of SEMA racking systems.

By following these steps, businesses can significantly reduce the risk of damage to SEMA racking systems and enhance workplace safety.

Regular inspections and maintenance are essential for ensuring the proper functioning and longevity of SEMA racking systems.

Illustrative Example: There was a company that neglected to perform regular inspections and maintenance for their SEMA racking system. Unfortunately, one day a bent beam went unnoticed, resulting in a collapse and causing damage to valuable inventory. This incident resulted in significant financial losses and served as a stark reminder of the importance of regular inspections and maintenance.

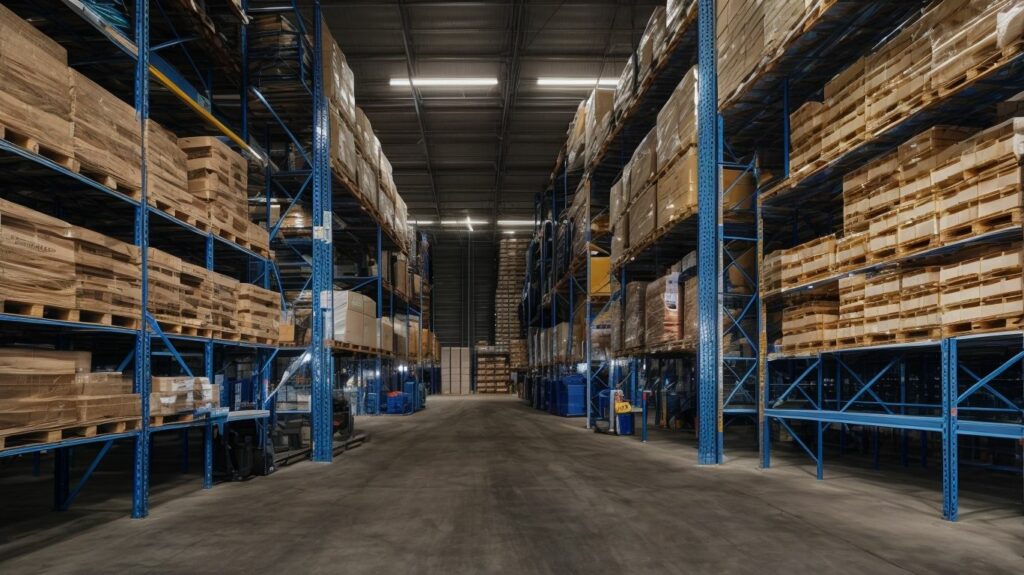

SEMA rack repair refers to the process of repairing damaged racking systems in warehouses and storage facilities. It is crucial for business operations as it ensures the safety of employees and the efficient functioning of the storage equipment. Regular maintenance, including SEMA-approved repairs, is necessary to create a safe environment and meet legal responsibilities.

SEMA approved rack repairs offer several benefits. Firstly, they prioritize safety, ensuring that the racking systems are in good working order and can hold materials safely above employees’ heads. Secondly, these repairs help minimize downtime by being carried out onsite, allowing businesses to maintain their operations without significant interruptions. Lastly, SEMA approved rack repairs are conducted by highly experienced rack repairers who work efficiently to ensure both safety and productivity.

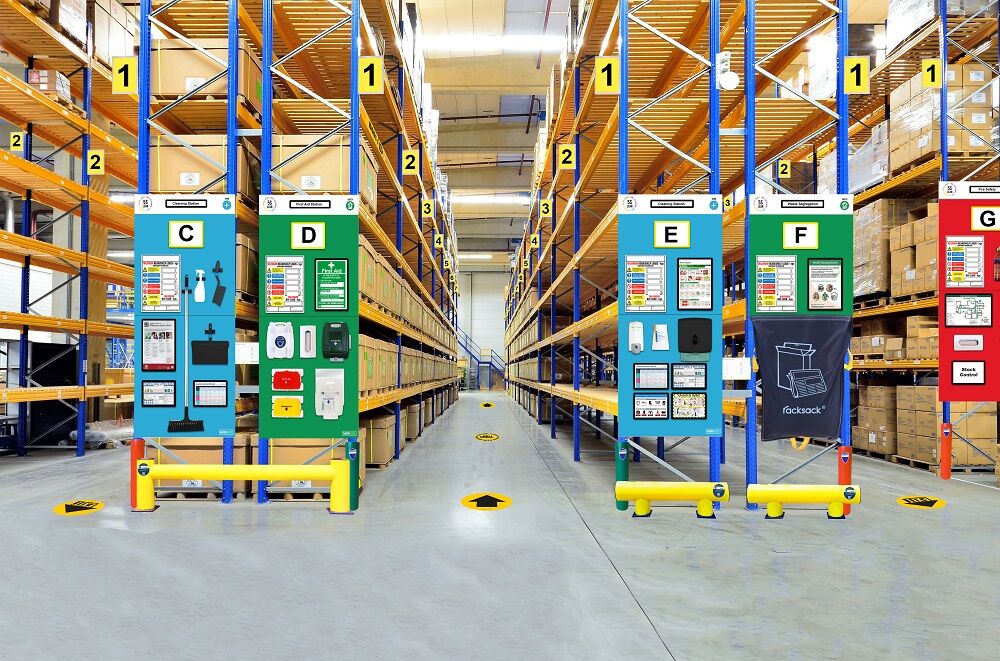

Regular racking maintenance is crucial for several reasons. It helps create a safe working environment by identifying and addressing any issues or damages to the racking systems. Maintenance ensures that the racking system is designed to meet its intended purpose, including the space it occupies, clearances, and carrying capacity. It also ensures compliance with SEMA codes and standards, as well as the PUWER regulations, which are legal obligations for businesses.

A proper racking maintenance regime involves several key components. Firstly, staff should be trained to be safety aware and encouraged to report any problems immediately to address them promptly. Regular inspections should be conducted by a designated staff member to ensure proper use, check for damaged components, and ensure load notice guidance is followed. Additionally, investing in training for warehouse staff, including the SEMA Rack Safety Awareness course, is recommended. Lastly, expert inspections by SEMA Approved Racking Inspectors (SARIs) should be conducted to assess the compatibility and suitability of the equipment, rack configuration, and use of load notices.

The traffic light system is used in SARI inspection reports to indicate the severity of damage and the necessary actions. Red risk areas indicate high levels of damage and require immediate offloading and discontinuation of use. Amber risk areas indicate severe damage that requires remedial work, and pallet positions should not be refilled until repairs are carried out. If repairs are not completed within four weeks, an Amber risk item automatically becomes a Red risk item. This system helps prioritize and address the most critical repair needs.

We Aim To Reply To All Enquiries With-in 24-Hours